1. Introduction

Just 24 hours ago, a major European data center operator announced a $500 million expansion focused on AI infrastructure—and quietly revealed they’re using solid copper earth rods for lightning protection across all new facilities. Why? Because when milliseconds matter and downtime costs millions, only pure or copper-bonded grounding solutions deliver the reliability needed. This spotlight on copper’s critical role isn’t isolated—it’s part of a broader resurgence in niche copper rod applications that blend conductivity, corrosion resistance, and durability.

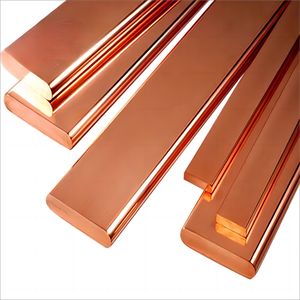

Copper rod might sound like a basic industrial material, but its specialized forms—like copper brazing rod, copper bonded ground rod, and flexible copper bus bar—are enabling breakthroughs in everything from renewable energy farms to spacecraft assembly. Let’s dive into seven lesser-known, high-impact uses of copper rod that are shaping tomorrow’s tech.

2. High-Reliability Earthing in Critical Infrastructure

In telecom hubs, hospitals, and financial trading floors, even a microsecond of electrical noise can crash systems. That’s where copper earth rod and copper clad steel earth rod come in. Unlike standard steel rods, copper-bonded or copper-clad variants offer decades of corrosion resistance while maintaining low earth resistance.

- Copper bonded earthing rod combines the tensile strength of steel with the conductivity of copper.

- The copper earth strip 25x3mm price is often justified by its 30+ year service life in harsh soils.

Engineers increasingly specify copper strip for earthing over bare wire due to its mechanical stability and ease of bonding.

3. Precision Brazing in Aerospace & HVAC

When joining copper to copper in sensitive systems—like aircon copper tube networks or satellite coolant lines—standard welding can warp thin walls. Enter copper to copper brazing rods. These filler metals melt below base metal temperatures, preserving structural integrity.

Copper brazing rod is preferred for air conditioning copper pipe repairs because it creates leak-proof joints without compromising the 15mm copper tube’s flexibility. Technicians also favor copper rod for welding delicate refrigerant lines where ac copper pipe price already reflects high purity requirements.

4. Flexible Busbars in Electric Vehicles

Modern EV battery packs demand compact, vibration-resistant power distribution. Flexible copper bus bar—often made from layered thin copper strips—handles high current while absorbing chassis movement. Nickel plated copper strip variants reduce contact resistance at connection points.

Unlike rigid copper bar, flexible versions use laminated copper metal strips that maintain conductivity under constant flexing—critical for longevity in fast-charging stations and onboard inverters.

5. Scrap Recovery & Wire Reclamation

Recycling operations rely heavily on efficient copper recovery. Stripping copper wire for scrap has evolved beyond burning copper wire for scrap (a hazardous practice now banned in many regions).

- The best way to strip copper cable involves automated machines that cleanly separate insulation from 1mm copper strip or thicker conductors.

- For recyclers, the fast way to strip copper wire preserves metal value—burning degrades purity and fetches lower copper ingot price.

Demand for stripping wire for recycling continues to grow as global e-waste surges, making clean copper strip near me a hot commodity for urban mining startups.

6. Architectural Detailing & Pest Control

Beyond electronics, copper finds quirky yet functional roles. Copper roof strip and copper edging strip prevent moss and algae buildup thanks to natural biocidal properties. Even more niche: copper tape for snails is used by organic gardeners to deter mollusks without chemicals.

These applications use flat copper strip or copper strip roll in widths as narrow as 10mm. Though seemingly trivial, they showcase copper’s versatility beyond industrial contexts.

7. High-Frequency Grounding in 5G & Radar Systems

As 5G towers multiply, signal integrity demands ultra-low impedance paths to ground. Here, copper clad ground rod and copper bonded steel outperform alternatives. Their seamless conductivity minimizes RF interference—a must for mmWave frequencies.

Installation teams often pair these with copper strip wire bonded directly to antenna mounts, ensuring every component shares the same ground potential. Even small differences in earthing rod price are outweighed by performance gains in dense urban deployments.

8. Conclusion

From shielding AI data centers to enabling cleaner EVs and smarter recycling, copper rod in its many specialized forms remains a silent enabler of modern innovation. Whether it’s a copper round bar machined into aerospace fittings or a copper beryllium strip in high-stress connectors, this metal continues to prove that sometimes, the oldest solutions are still the best—for grounding, joining, conducting, and protecting our most advanced systems.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 7. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.