Overview of copper bar

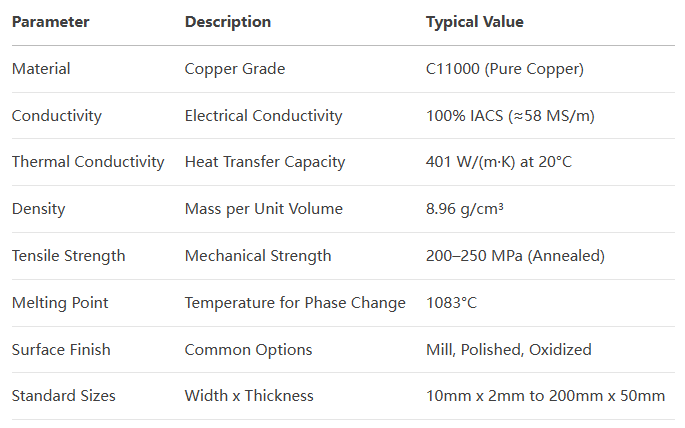

Copper bars are widely used in electrical, construction, and industrial applications due to copper’s excellent electrical conductivity, thermal conductivity, and formability. Here are some key parameters for copper bars:

- Chemical Composition: Pure copper bars are primarily composed of copper (Cu), with a minimum copper content of 99.9% for electrolytic tough pitch (ETP) copper and 99.95% for oxygen-free copper (OFC). Impurities like oxygen, silver, iron, sulfur, and phosphorus may be present in trace amounts.

- Standard Designations: Copper bars adhere to various international standards, such as ASTM B152 for copper sheet, plate, strip, and rolled bar, and ASTM B187 for copper bus bar. Other common standards include C10100 (OFHC – Oxygen-Free High Thermal Conductivity), C10200 (ETP – Electrolytic Tough Pitch), and C12200 (DWV – Drain, Waste, Vent).

- Dimensions: Copper bars come in various sizes, with dimensions specified by diameter, width, and length. Diameter can range from small rods (e.g., 1/4 inch) to large bars (up to several inches), while lengths can vary greatly, often custom-cut to customer specifications.

- Density: The density of pure copper is approximately 8.96 g/cm³.

- Melting Point: The melting point of copper is 1084°C (1983°F).

- Conductivity: Copper is an excellent conductor of electricity and heat. Electrical conductivity for ETP copper is around 58 MS/m (at 20°C), while OFHC copper can have conductivity up to 101 MS/m.

- Thermal Conductivity: Copper’s thermal conductivity is around 385 W/(m·K) for ETP and up to 401 W/(m·K) for OFHC at room temperature.

- Tensile Strength: The tensile strength of copper bars varies depending on the alloy and temper, ranging from approximately 200 to 520 MPa (30,000 to 75,000 psi).

- Elongation: Elongation at break, a measure of ductility, can range from 20% to 50%, depending on the copper grade and processing.

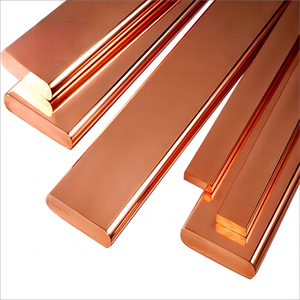

- Finish: Copper bars can be supplied in various finishes, including smooth-drawn, bright annealed, or rough-cut, depending on the intended application.

- Corrosion Resistance: Copper is naturally corrosion-resistant, especially in atmospheric and marine environments, though it can corrode in the presence of certain acids and salts.

- Typical Applications: Copper bars are used in electrical conductors, bus bars, heat exchangers, architectural applications, sculptures, and a variety of industrial machineries and components where high electrical and thermal conductivity is required.

copper bar

Characteristics and advantages of copper bar

Excellent conductivity: The conductivity of copper is second only to silver, which is suitable for power transmission and electronic components.

High thermal conductivity: Commonly used in scenarios where rapid heat conduction is required, such as radiators and heat exchangers.

Corrosion resistance: Strong antioxidant ability, especially high stability in non-acidic environments.

Ductility and plasticity: Easy to process into different shapes (such as rolling and drawing).

Antibacterial properties: Natural antibacterial properties, suitable for medical and health-related fields.

Specifications of copper bar

Application of copper bar

Electrical industry: busbars, cables, transformer windings.

Architectural decoration: roofs, sculptures, hardware accessories.

Industrial manufacturing: heat exchangers, bearings, mechanical parts.

Electronic equipment: PCB circuit boards, connectors.

Other uses: currency, artwork, antibacterial surfaces.

Company Profile

Copper-group is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality copper and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality copper products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods of Copper bar

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment of Copper bar

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of copper bar

What are the common types of materials for copper strips?

Pure copper (T1/T2), oxygen-free copper (TU1/TU2), phosphorus deoxidized copper (TP1/TP2), etc.

How to deal with the oxidation on the surface of copper strips?

Slight oxidation can be wiped with citric acid or special detergent, and severe oxidation requires mechanical polishing.

Is the copper strip suitable for outdoor use?

Yes, but long-term exposure requires rust prevention (such as tin plating or protective paint).

Is the conductivity of copper strips affected by temperature?

Yes, when the temperature rises, the resistance increases and the conductivity decreases slightly.

How to distinguish pure copper from copper-plated products?

Scrape the surface to see if the color is consistent, or measure the density (the density of pure copper is 8.96 g/cm³).