1. Introduction

In the past 48 hours, global copper prices surged by over 2% following news of production cuts at major mines in Chile and Peru, reigniting interest in copper material efficiency and alternatives like copper bonded steel. This volatility makes it more critical than ever to understand the nuances between different copper rod and strip products—whether you’re grounding a building, welding HVAC components, or stripping wire for scrap.

Copper rod isn’t just one thing. From solid round bars used in electrical bus systems to specialized rods for brazing or earthing, each variant serves a distinct purpose. Similarly, copper strips come in dozens of alloys, thicknesses, and platings—each optimized for conductivity, corrosion resistance, or mechanical strength.

2. Copper Rod Variants: Purpose-Built for Performance

2.1. Earthing and Grounding Rods

When it comes to safety grounding, the terms copper earth rod, earthing rod copper, and ground rod copper are often used interchangeably—but the materials underneath differ significantly.

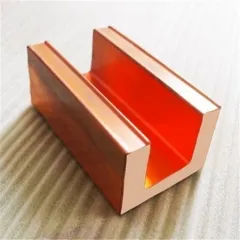

Solid copper rods offer the highest conductivity and corrosion resistance but come at a premium price. In contrast, copper bonded earthing rods (also called copper bonded ground rods or copper clad steel ground rods) feature a steel core with a thick electrolytic copper coating. These combine the tensile strength of steel with copper’s conductivity, making them ideal for rocky or high-resistivity soils.

- Copper bonded steel rods typically contain 99.9% pure copper cladding.

- They cost 30–50% less than solid copper rods, influencing earthing rod price decisions for large-scale projects.

- Copper clad earth rods and copper clad steel earth rods meet IEEE and IEC standards for grounding systems.

2.2. Welding and Brazing Rods

For joining copper components—especially in HVAC or plumbing—specialized filler rods are essential. Copper brazing rod and copper to copper brazing rods are designed for capillary action and strong metallurgical bonds without melting the base metal.

Copper welding rod options include phosphorus-deoxidized types (like CuP6) that prevent porosity during copper rod welding. Meanwhile, copper to copper welding rod formulations ensure compatibility and minimize thermal stress.

Note: While ‘welding rod copper’ is a common search term, true fusion welding of copper often requires TIG or MIG with inert gas—brazing remains the go-to for most field applications.

3. Copper Strips: From Earthing to Electronics

3.1. Flat Strip Variants and Alloys

Flat copper strip applications span from copper strip for earthing in substations to precision beryllium copper strip in aerospace connectors. Common sizes like 25x3mm or 1mm copper strip are stocked globally, with copper strip price varying by alloy and temper.

Popular types include:

- Nickel plated copper strip: enhances solderability and reduces oxidation.

- Beryllium copper strip (or copper beryllium strip): offers high strength and non-sparking properties.

- Flexible copper bus bar: made from laminated thin copper strips for dynamic current distribution.

Rolls of copper strip—whether as copper strip roll or roll of copper strip—are favored for custom cutting in manufacturing.

3.2. Scrap and Recycling Considerations

With copper scrap values climbing, many ask: is stripping copper wire worth it? Absolutely—if done right.

The best way to strip copper wire avoids burning (which degrades quality and violates environmental codes). Instead, mechanical strippers or automated machines offer a fast way to strip copper wire while preserving purity for resale.

- Never burn copper wire for scrap—it releases toxic fumes and lowers recovery value.

- Stripping wire for recycling yields higher returns when insulation is cleanly removed.

- For thick cables, industrial strippers or hydraulic cutters are recommended over manual methods.

Searches like ‘copper strip near me’ or ‘stripping copper wire for scrap’ reflect growing DIY and small-business interest in copper recovery.

4. Copper Rod vs. Round Bar vs. Strip: Clarifying Terminology

Confusion often arises between copper rod, copper round bar, and round bar copper. Technically, all refer to solid cylindrical copper stock—but ‘rod’ implies smaller diameters (<1 inch), while 'bar' suggests larger, structural sizes.

Similarly, copper bar and cu bars may describe rectangular or square profiles used in busbars or machining. Flexible copper bar variants serve high-vibration environments like electric vehicles.

Copper ingot and copper ingot price matter at the production level, as they’re melted to cast rods, bars, or strips. Meanwhile, 1oz copper price tracks commodity markets but rarely reflects fabricated product costs.

5. Integration with Copper Piping Systems

Though not rods per se, copper pipework and air conditioning copper pipe often interface with copper rods in HVAC installations. For example, copper pipe for AC systems may be brazed using copper rod for welding to ensure leak-free joints.

Common sizes like 15mm copper pipe, 22mm copper tube, or 3/4 copper tubing rely on compatible copper pipe fittings and proper copper pipe soldering techniques.

Professionals increasingly compare copper with PEX plumbing pipes—but copper remains unmatched for thermal stability and recyclability in critical applications.

6. Conclusion

Whether you’re selecting an earthing rod copper for a data center, sourcing copper to copper brazing rods for refrigeration work, or evaluating copper strip price for a custom busbar, material choice directly impacts performance, safety, and cost. With copper markets in flux, understanding the differences between solid, bonded, and clad options—and knowing the best way to strip copper wire for scrap—can deliver significant operational and financial advantages.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Copper. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.