1. Introduction

Just 24 hours ago, the London Metal Exchange reported a 3.2% surge in copper prices—the sharpest single-day jump in six weeks—fueled by rising demand from renewable energy and EV infrastructure projects. This spike has reignited interest in copper-based components like copper rod, copper strip, and earthing systems, especially among contractors, recyclers, and manufacturers.

Whether you’re installing a grounding system, welding copper pipes, or stripping scrap wire, understanding the nuances between different copper forms is critical. In this deep dive, we’ll compare solid copper rods with copper-bonded and copper-clad variants, analyze copper strip types, and clarify which options deliver the best performance—and value—for specific applications.

2. Copper Rod Variants: Solid, Bonded, or Clad?

Not all copper rods are created equal. The term ‘copper rod’ broadly covers several distinct products, each engineered for unique purposes.

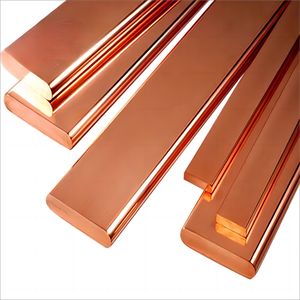

Solid copper rod—often called rod copper or copper round bar—is made from high-purity electrolytic copper (typically 99.9% Cu). It’s the gold standard for electrical conductivity and corrosion resistance, commonly used in bus bars, grounding electrodes, and high-end welding.

In contrast, copper bonded earthing rod and copper clad ground rod offer cost-effective alternatives. These consist of a steel core (for tensile strength) coated with a layer of copper—either through molecular bonding (copper bonded steel) or metallurgical cladding (copper clad steel earth rod). While they sacrifice some conductivity, they retain decent corrosion resistance at a fraction of the copper rod price.

- Copper bonded earthing rod: Ideal for rocky soils where mechanical strength matters.

- Copper clad steel ground rod: Better for high-moisture environments due to uniform copper coverage.

- Solid copper earth rod: Best for critical infrastructure like telecom towers or substations.

When choosing an earthing rod copper solution, consider soil chemistry, expected lifespan, and local electrical codes. For most residential uses, copper bonded ground rods strike a smart balance between performance and cost.

3. Welding and Brazing: Which Copper Rod Fits the Job?

Confusion often arises between copper welding rod and copper brazing rod. Despite similar names, they serve very different functions.

Copper to copper welding rod is used in true fusion welding (like TIG), where both base metals melt. However, pure copper’s high thermal conductivity makes this challenging without preheating. Hence, many opt for copper brazing instead.

Copper brazing rod—often phosphorus-copper alloys—melts at lower temps and flows into joints without melting the base metal. Copper to copper brazing rods are widely used in HVAC and plumbing for joining aircon copper pipe or copper tubing.

For DIYers or HVAC technicians working with 15mm copper pipe or 22mm copper tube, brazing with a copper brazing rod is faster, safer, and more reliable than attempting full copper rod welding.

4. Copper Strip: From Earthing to Scrap Recycling

Beyond rods, copper strip (also called copper stip, flat copper strip, or copper metal strips) plays a vital role in electrical grounding, RF shielding, and even snail deterrents (yes, copper tape for snails is a real gardening hack!).

Common variants include:

- 1mm copper strip and 25x3mm copper earth strip: Used in substation grounding.

- Beryllium copper strip and copper beryllium strip: High-strength alloys for springs and connectors.

- Nickel plated copper strip: Enhanced corrosion resistance for marine electronics.

- Thin copper strips in roll form: Ideal for flexible bus bars or EMI shielding.

Pricing varies widely. A copper strip roll might cost $15–$40 per kg, while specialty alloys like beryllium copper strip can exceed $100/kg. Always check ‘copper strip price’ locally—searching ‘copper strip near me’ often yields better deals from metal suppliers than online retailers.

5. Stripping Copper Wire: Profitable or Perilous?

With copper prices climbing, many are asking: is stripping copper wire worth it? The answer: yes—but only if done safely and legally.

The best way to strip copper wire involves mechanical strippers or automated machines—not burning. Burning copper wire for scrap releases toxic fumes and degrades copper quality, reducing resale value. Plus, it’s illegal in many regions.

For recyclers, the fast way to strip copper wire includes:

- Using a manual wire stripper for small batches.

- Investing in a cable granulator for stripping wire for scrap at scale.

- Avoiding acid or fire—both harm the environment and your profits.

Remember: clean, bare copper fetches the highest price. Whether you’re stripping copper wire for scrap or salvaging copper pipe fittings, purity matters more than speed.

6. Conclusion

From solid copper round bar to copper clad steel earth rod, the right choice depends on your application’s electrical, mechanical, and budgetary needs. With copper rod price and copper strip price trending upward, understanding these distinctions isn’t just technical—it’s financial. Whether you’re grounding a building, brazing aircon copper tube, or recycling stripped wire, prioritize quality, safety, and compliance to maximize value in today’s volatile copper market.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Copper. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.