1. Introduction

As of June 2024, global copper markets are experiencing heightened volatility due to increased demand from green energy projects and electric vehicle manufacturing, coupled with constrained mining output in Chile and Peru. According to the International Copper Study Group (ICSG), refined copper demand is projected to grow by 3.2% this year, directly impacting the pricing and availability of copper-based products—including copper rod, copper strip, and specialized variants like copper bonded earthing rods.

In this context, professionals across electrical engineering, construction, HVAC, and metal recycling must understand the distinctions between different copper forms. This article delivers a deep-dive analysis of copper rod types—from grounding applications to welding—and examines the expanding role of copper strips in earthing, roofing, and electronics.

2. Copper Rod Variants and Their Applications

2.1. Earthing and Grounding Rods

Copper earth rods—also referred to as earthing rod copper or ground rod copper—are critical for electrical safety systems. Pure copper rods offer excellent conductivity and corrosion resistance but are costly. As a cost-effective alternative, copper bonded earthing rods and copper clad steel ground rods combine a steel core with a copper layer. Copper bonded steel features a molecular bond between copper and steel, offering superior durability over copper clad earth rods, which rely on a mechanical or electroplated bond.

The copper earth strip 25x3mm price and earthing rod price vary significantly based on copper content. While solid copper rods may cost 30–50% more, copper bonded variants provide a balance of performance and affordability, especially in large-scale infrastructure projects.

2.2. Welding and Brazing Rods

Copper welding rod and copper brazing rod serve distinct purposes in metal joining. Copper to copper welding rods are used in applications requiring high thermal conductivity, such as heat exchangers or electrical busbars. However, pure copper is difficult to weld due to its high thermal diffusivity; thus, alloys like phosphor bronze or silicon bronze are often preferred.

For brazing, copper to copper brazing rods—typically composed of copper-phosphorus alloys—enable strong, flux-free joints in refrigeration and plumbing systems. Copper rod for welding must be selected based on base metal compatibility, joint design, and service environment. Misapplication can lead to brittle joints or thermal stress cracking.

3. Copper Strips: From Earthing to Electronics

3.1. Types and Industrial Uses

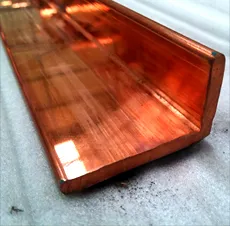

Flat copper strip, including 1mm copper strip and thin copper strips, is widely used in electrical grounding, transformer windings, and flexible busbars. Beryllium copper strip and copper beryllium strip offer enhanced strength and spring properties, making them ideal for connectors and switches. Nickel plated copper strip improves solderability and corrosion resistance in high-reliability electronics.

Copper strip for earthing is commonly specified in substation grounding grids, while copper roof strip and copper edging strip serve architectural functions. The copper strip price depends on thickness, alloy, and form—roll of copper strip versus cut lengths—and can be sourced as copper strip near me through specialized metal suppliers.

3.2. Recycling and Wire Stripping

The scrap value of copper has intensified interest in stripping copper wire. The best way to strip copper wire involves mechanical strippers for insulated cables, while the fast way to strip copper wire for bulk recycling often uses automated machines. Burning copper wire for scrap is discouraged due to toxic fumes and legal restrictions in many regions.

Professionals engaged in stripping wire for recycling must distinguish between solid core and stranded conductors. Stripping copper wire for scrap yields higher returns when insulation is cleanly removed, preserving the purity of the copper metal strips. The best way to strip copper cable without damaging the conductor ensures maximum resale value.

4. Copper Round Bar and Related Products

Copper round bar—synonymous with rod copper or round bar copper—is used in machining, electrical components, and as feedstock for drawing wire. Available in various tempers and diameters, copper bars for sale include flexible copper bar and flexible copper bus bar configurations for dynamic electrical connections.

Cu bars and copper ingot price trends directly influence copper rod price and copper bar top availability. With 1oz copper price hovering near multi-year highs, fabricators increasingly consider copper alloy strip or recycled content to manage costs without compromising performance.

5. Integration with Copper Piping Systems

While not rods per se, copper pipework and air conditioning copper pipe systems often interface with copper rods and strips in grounding and bonding applications. For instance, 15mm copper pipe and 22mm copper tube installations in HVAC systems require proper earthing using copper strip or dedicated ground rods.

Soldering practices—such as copper pipe soldering and resoldering copper pipe—must align with electrical safety codes that mandate bonding to a copper earth strip or rod. The ac copper pipe price and aircon copper tube costs are rising, reinforcing the need for efficient material use and proper grounding integration.

6. Conclusion

From copper bonded ground rods to beryllium copper strip and copper to copper welding rods, the diversity of copper-based products reflects their irreplaceable role in modern infrastructure. As copper prices remain elevated and sustainability drives recycling innovation, selecting the right form—whether solid, bonded, or clad—is crucial for performance, compliance, and cost-efficiency. Understanding these nuances ensures optimal application across electrical, construction, and industrial sectors.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Copper. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.