1. Introduction

Just 24 hours ago, a major European data center operator announced it had upgraded its entire grounding infrastructure using copper bonded earthing rods to meet new EU electromagnetic compatibility standards. This move highlights how even behind-the-scenes components like the copper rod are critical in today’s tech-driven world. Far beyond basic plumbing or wiring, copper rod and its derivatives serve highly specialized roles in fields ranging from renewable energy to microelectronics.

In this article, we’ll dive into seven niche—but vital—applications of copper rod that most people never see, yet rely on daily. Whether it’s ensuring lightning-safe skyscrapers or enabling ultra-precise robotic joints, copper’s conductivity, corrosion resistance, and malleability make it irreplaceable.

2. High-Reliability Grounding with Copper Earth Rods

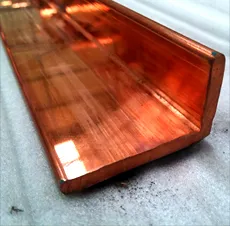

One of the most critical yet overlooked uses of copper rod is in earthing systems for sensitive infrastructure. Copper earth rods—especially copper bonded ground rods and copper clad steel earth rods—are engineered for long-term soil contact without degrading. Unlike pure copper rods, which can be costly, copper bonded variants offer the conductivity of copper with the tensile strength of steel.

These rods are standard in telecom towers, hospitals, and data centers where even a microsecond of electrical instability can cause system failure. The earthing rod price varies based on length and coating thickness, but engineers consistently choose copper bonded options for their balance of performance and cost.

3. Precision Joining with Copper Brazing and Welding Rods

In aerospace and HVAC manufacturing, joining copper components without compromising thermal performance is essential. That’s where copper brazing rod and copper to copper brazing rods come in. These filler metals melt at lower temperatures than base copper, allowing clean, strong joints in aircon copper tubes and heat exchangers.

Similarly, copper welding rod (or copper rod for welding) is used in repair scenarios where traditional solder won’t hold. Copper to copper welding rod ensures seamless conductivity in bus bars or transformer windings. Unlike burning copper wire for scrap—a destructive practice frowned upon in professional settings—proper copper rod welding preserves material integrity.

4. Flexible Power Distribution via Copper Bus Bars and Strips

Modern electric vehicles and solar inverters demand compact, high-current conductors. Enter the flexible copper bus bar and flat copper strip. Made from rolled round bar copper or thin copper strips, these components handle surges while fitting into tight spaces.

Specialized variants like beryllium copper strip or nickel plated copper strip add springiness or oxidation resistance—key for battery connectors or relay contacts. A 1mm copper strip might seem flimsy, but when layered or corrugated, it becomes a powerhouse conductor. And yes, you can find copper strip near me through industrial suppliers, often sold as a roll of copper strip for custom cutting.

5. Advanced Earthing with Copper Strip Systems

Beyond rods, flat conductors play a starring role in grounding. Copper strip for earthing—often specified as copper earth strip 25x3mm—is laid in grids beneath server rooms or substations to create equipotential zones. This prevents voltage differentials during faults.

Unlike stripping copper wire for scrap, which focuses on recovery value, installing copper strip requires precision: clean bends, secure clamps, and corrosion-resistant joints. The copper strip price reflects its purity and dimensional accuracy, especially for oxygen-free grades used in labs and cleanrooms.

6. Micro-Electronics and Sensor Integration

Thin copper strips aren’t just for power—they’re also signal carriers. In medical devices and IoT sensors, copper alloy strip (like copper beryllium strip) provides both conductivity and mechanical resilience. These metal strips act as flexible printed circuit interconnects or strain gauges.

Interestingly, even ‘copper tape for snails’—a gardening product—shares manufacturing roots with electronic-grade copperstrip. Both start as wide rolls slit into precise widths, though only the latter undergoes rigorous conductivity testing.

7. Sustainable Recovery and Reuse

As e-waste grows, so does interest in ethical copper recovery. The best way to strip copper wire isn’t burning—it’s mechanical stripping using automated tools that preserve insulation and metal quality. Stripping wire for recycling this way yields clean copper that can be re-melted into ingots, then drawn into new copper round bar or rod copper for industrial reuse.

Scrap yards now pay premium rates for properly stripped copper cable, making the fast way to strip copper wire not just eco-friendly but profitable. From old AC copper pipe to retired bus bars, recycled copper feeds back into high-value applications—closing the loop sustainably.

8. Conclusion

The copper rod is far more than a commodity—it’s a foundational element in technologies pushing the boundaries of efficiency, safety, and miniaturization. Whether as a copper clad ground rod anchoring a wind farm or a beryllium copper strip enabling robotic surgery, its niche roles are quietly shaping our future. Next time you see copper tubing or a copper bar, remember: there’s likely an advanced application behind it you never knew existed.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 7. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.