1. Introduction

Just 24 hours ago, global copper prices surged past $9,800 per metric ton amid supply chain disruptions in Chile—the world’s top copper producer—sparking renewed interest in copper material efficiency and substitution strategies across construction, electrical, and recycling sectors. With costs rising, knowing exactly which copper form you need—whether it’s a copper rod for grounding, a copper strip for busbars, or copper tubing for AC systems—is more critical than ever.

Copper comes in many shapes: rods, strips, pipes, bars, and wires. But confusing them can lead to costly mistakes, failed installations, or even safety hazards. In this deep dive, we’ll compare three core categories—copper rod, copper strip, and copper pipe—and break down their subtypes, uses, pros, cons, and current market realities.

2. Copper Rod: More Than Just a Solid Bar

When people say ‘copper rod,’ they often mean one of several specialized variants. The term ‘rod copper’ broadly refers to solid cylindrical copper stock, but its application defines its exact type.

Earthing rods are among the most common. A copper earth rod—or ground rod copper—is driven into soil to safely dissipate electrical faults. Pure copper rods offer excellent conductivity but are expensive and soft. That’s why many opt for copper bonded earthing rods: steel cores coated with a thick layer of electrolytic copper (typically 0.25mm+). These combine strength with corrosion resistance at a lower cost. Similarly, copper clad steel ground rods (also called copper clad earth rods) use metallurgical bonding for durability. Prices vary widely—earthing rod price depends on length, coating thickness, and whether it’s solid or bonded.

On the fabrication side, copper brazing rod and copper welding rod serve entirely different purposes. Copper to copper brazing rods (often phosphorus-deoxidized) are used with a torch and flux to join copper pipes without melting the base metal—ideal for plumbing. In contrast, copper rod for welding—like ECuSn-A or ECuAl-A2 alloys—is used in arc or TIG processes for joining dissimilar metals. Note: pure ‘copper to copper welding rod’ is rare; most welding rods are copper alloys for better strength.

3. Copper Strip: The Flat Power Conductor

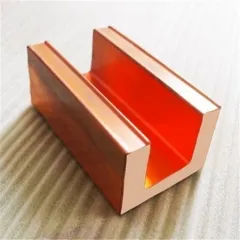

Unlike round rod copper, copper strip is flat and thin—perfect for electrical busbars, grounding straps, or RF shielding. You’ll see terms like flat copper strip, thin copper strips, or 1mm copper strip depending on thickness. Beryllium copper strip (or copper beryllium strip) adds springiness and strength for connectors, while nickel plated copper strip resists oxidation in harsh environments.

For earthing, copper strip for earthing—such as the standard 25x3mm size—is often preferred over rods in substations due to lower impedance. Pricing? Check ‘copper strip price’ or ‘copper earth strip 25x3mm price’—it fluctuates with LME rates. Rolls are common: copper strip roll or roll of copper strip makes installation easier for long runs.

Recyclers often search ‘stripping copper wire for scrap’ or ‘best way to strip copper cable.’ But beware: ‘burning copper wire for scrap’ releases toxic fumes and degrades value. Mechanical strippers are safer and preserve purity. And no, ‘copper tape for snails’ (a gardening product) has nothing to do with electrical strips—don’t confuse ‘copper stip’ or ‘copperstrip’ typos!

4. Copper Pipe: Plumbing and HVAC Workhorse

Copper pipe tube dominates residential plumbing and air conditioning systems. Aircon copper pipe (or ac copper pipe) comes in types L, M, and K—differing in wall thickness. Type L (thicker) is used underground; Type M (thinner) for interior lines. Common sizes include 15mm copper pipe, 22mm copper tube, and 3/4 copper tubing.

Soldering is key: copper pipe soldering requires clean surfaces, proper flux, and lead-free solder. Resoldering copper pipe joints without removal is tricky but possible with careful heat control. Always match fittings—copper pipe fittings must align with pipe sizing to avoid leaks.

Pricing is volatile: check ‘ac copper pipe price’ or ‘copper tube price’ weekly. Alternatives like PEX plumbing pipes are gaining ground due to cost, but copper remains king for durability and thermal performance in HVAC.

5. Choosing the Right Form: Practical Guidance

- Need grounding? Use solid copper earth rod for corrosive soils; copper bonded steel for rocky terrain.

- Joining copper pipes? Use copper to copper brazing rods—not welding rods.

- Building a busbar? Flexible copper bus bar or nickel plated copper strip offers reliability.

- Recycling wire? Invest in a fast way to strip copper wire mechanically—skip burning.

- Installing AC lines? Stick to 1/2 copper pipe or 3/4 copper tubing based on BTU load and copper pipe sizing charts.

6. Conclusion

Copper rod, strip, and pipe each serve distinct roles shaped by form, alloy, and application. Whether you’re comparing earthing rod price versus copper bonded options, sourcing copper strip near me for a panel build, or selecting the right air conditioner copper pipe price point, understanding these differences prevents waste and ensures performance. As copper markets tighten, precision in material selection isn’t just smart—it’s essential.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What’s. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.