1. Introduction

Let’s be honest: when you hear ‘copper rod,’ your mind probably doesn’t race to visions of high-stakes engineering drama. But behind the scenes of everything from data centers to air conditioning units, copper rods are the unsung heroes quietly conducting electricity, grounding lightning bolts, and fusing metal with the grace of a metallurgical ballet dancer. Forget capes—these rods wear conductivity ratings and corrosion resistance like badges of honor. In this deep dive, we’ll explore two niche yet vital applications of copper rod: ultra-reliable earthing systems and precision copper-to-copper welding. Spoiler alert: it’s not just about the copper rod price—it’s about performance under pressure.

2. Copper Rod in Advanced Earthing Systems

When lightning strikes—or worse, when a fault current surges through a substation—the first line of defense isn’t a superhero. It’s a copper earth rod. Specifically, a copper bonded earthing rod or copper clad steel earth rod buried deep in the soil, silently channeling thousands of amps safely into the ground. These aren’t your average garden stakes; they’re engineered for decades of service in corrosive environments.

2.1. Why Copper? Why Not Just Any Metal?

Copper’s electrical conductivity is second only to silver, but unlike silver, it won’t bankrupt your project. More importantly, copper resists corrosion far better than steel or aluminum—critical for earthing rods that must maintain low resistance over 25+ years. That’s why professionals opt for copper bonded ground rods or copper clad steel ground rods: they combine the tensile strength of steel with the surface conductivity and corrosion resistance of copper. The result? A ground rod copper solution that’s tough, efficient, and cost-effective.

2.2. From Rod to Strip: The Earthing Ecosystem

While the copper earth rod handles vertical grounding, horizontal connections often rely on flat copper strip—like the ubiquitous copper earth strip 25x3mm. This copper strip for earthing links rods, equipment frames, and lightning arresters into a unified grounding grid. Need flexibility? Enter the flexible copper bus bar or nickel plated copper strip for high-frequency applications. And yes, if you’re wondering about copper strip price or searching for ‘copper strip near me,’ rest assured: this isn’t scrap—it’s system-critical infrastructure.

3. Copper Rod in Precision Welding and Brazing

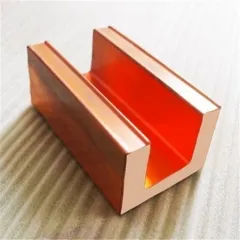

Now, shift gears from grounding to joining. In HVAC, refrigeration, and high-purity piping systems, copper-to-copper joints must be leak-proof, strong, and thermally stable. That’s where copper brazing rod and copper welding rod shine. Unlike steel welding, copper rod welding demands finesse—copper’s high thermal conductivity means you’re fighting a heat sink, not a passive metal.

3.1. Brazing vs. Welding: The Copper Conundrum

Technically, most ‘copper rod for welding’ applications actually use brazing—a process where a copper to copper brazing rod (often phosphorus-deoxidized) melts at lower temps than the base metal, flowing into the joint via capillary action. True copper welding rod is rarer and used for thick sections or dissimilar metals. Either way, the goal is a seamless, conductive, and pressure-tight bond—essential for aircon copper pipe systems that carry refrigerant under stress.

3.2. The HVAC Connection: Where Rod Meets Tube

Speaking of air conditioning copper pipe, every 15mm copper tube or 22mm copper pipe in your AC unit likely started as a copper round bar, drawn into tubing, then joined with copper to copper welding rod or brazed with precision. The integrity of these joints affects efficiency, noise, and lifespan. Mess it up, and you’re not just fixing a leak—you’re recharging refrigerant and losing sleep. That’s why pros swear by high-quality copper brazing rods and meticulous copper pipe soldering techniques.

4. The Scrap Side: Stripping, Pricing, and Practicalities

Of course, not all copper rod journeys end in glory. Some meet the scrap yard. But before you start burning copper wire for scrap (please don’t—that’s illegal and toxic), consider the best way to strip copper wire. Whether it’s stripping copper wire for scrap or recycling copper strip wire, methods matter. Manual strippers, rotary machines, or even freezing insulation for easy removal—each has pros and cons. And if you’re eyeing that roll of copper strip or beryllium copper strip for resale, remember: purity affects value. Thin copper strips? 1mm copper strip? Even copper tape for snails (yes, really—it deters garden pests!)—it all adds up.

4.1. Price Watch: Rods, Strips, and Bars

Curious about copper rod price or copper ingot price? They fluctuate with the LME, but niche forms like copper bonded steel or beryllium copper strip command premiums for performance. Similarly, copper pipe price varies by type (L vs M), while copper bar top and flexible copper bar serve busbar applications in switchgear. Whether you’re sourcing copper bars for sale or comparing earthing rod price quotes, always factor in longevity—not just upfront cost.

5. Conclusion

From the depths of a substation’s grounding grid to the pressurized veins of an air conditioner, copper rod—and its cousins like copper strip, copper round bar, and copper brazing rod—prove that sometimes, the most critical components are the ones you never see. They don’t ask for applause; they just conduct, ground, and join with silent reliability. So next time you enjoy stable power or cool air, tip your hat to the humble copper rod. It’s not flashy, but without it, the whole system might just… short out.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Why. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.