1. Introduction

In the past 48 hours, the International Electrotechnical Commission (IEC) has reaffirmed updated safety guidelines for grounding systems in high-voltage substations, emphasizing the mandatory use of high-conductivity copper-based earthing components. This timely update underscores the growing reliance on specialized copper rod variants—particularly copper earth rods and copper bonded ground rods—in modern electrical infrastructure. Beyond grounding, copper rod also plays a pivotal role in precision metal joining, especially in applications demanding seamless copper-to-copper conductivity.

This article delves into two advanced, niche applications of copper rod: (1) its use in high-performance earthing systems and (2) its function in specialized welding and brazing operations. We will examine the technical distinctions between copper rod types, their material advantages, and market considerations such as copper rod price and earthing rod price.

2. Copper Rod in Advanced Electrical Earthing Systems

2.1. The Role of Copper Earth Rods in Safety-Critical Infrastructure

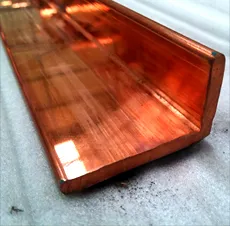

Copper earth rods—also referred to as earthing rod copper or ground rod copper—are engineered to provide low-resistance paths for fault currents into the earth. In data centers, power plants, and telecom towers, where electrical stability is non-negotiable, these rods ensure personnel safety and equipment protection. Pure copper rods offer superior corrosion resistance and electrical conductivity but are costly. Hence, alternatives like copper bonded earthing rods and copper clad steel earth rods have gained traction.

Copper bonded steel combines a steel core for mechanical strength with a thick electrolytic copper coating (typically 0.254 mm or more), offering a balance of durability and conductivity. Similarly, copper clad ground rods use metallurgical bonding to fuse copper to steel, making them ideal for rocky or corrosive soils. The copper earth strip 25x3mm price is often compared against rod-based solutions when designing meshed grounding grids.

2.2. Material Selection and Cost Considerations

When evaluating earthing rod price, engineers must weigh initial cost against lifecycle performance. While pure copper round bar installations offer the best conductivity, copper bonded options deliver 90% of the performance at a fraction of the copper rod price. For large-scale projects, copper strip for earthing—available as flat copper strip or copper strip roll—is often integrated with rods to create hybrid grounding networks.

3. Copper Rod in Precision Welding and Brazing

3.1. Copper-to-Copper Joining in Industrial Fabrication

In industries such as HVAC, electronics, and renewable energy, joining copper components without compromising thermal or electrical properties is essential. Here, copper welding rod and copper brazing rod are indispensable. Unlike steel welding, copper’s high thermal conductivity demands specialized filler materials. Copper to copper welding rod and copper to copper brazing rods are formulated to match the base metal’s composition, ensuring joint integrity and minimal resistivity.

Copper rod for welding is typically deoxidized (e.g., Cu-DHP) to prevent porosity during fusion. For brazing, phosphorus-containing copper brazing rods enable flux-free joining of copper pipes—critical in air conditioning copper pipe assemblies. The process, known as copper rod welding, requires precise temperature control but yields leak-proof, high-strength joints ideal for ac copper pipe systems.

3.2. Compatibility with Copper Tubing and Fittings

Welding rod copper is frequently used alongside copper pipe and fittings in HVAC retrofits and refrigeration lines. When repairing 15mm copper tube or 22mm copper pipe joints, technicians may opt for resoldering copper pipe or using copper brazing rods for permanent fixes. The compatibility between copper rod welding materials and standard copper tubing ensures seamless integration without galvanic corrosion risks.

4. Market Trends and Material Availability

Demand for copper bonded and copper clad variants continues to rise due to cost-efficiency and regulatory compliance. Meanwhile, recyclers increasingly seek stripping copper wire for scrap, though burning copper wire for scrap is discouraged due to environmental hazards. The best way to strip copper wire—mechanically, without damaging the conductor—supports the circular economy and supplies raw material for new copper round bar production.

For procurement, terms like copper strip near me, copper bars for sale, and copper ingot price reflect localized market dynamics. Thin copper strips, beryllium copper strip, and nickel plated copper strip serve niche roles in electronics and aerospace, while flexible copper bus bar solutions leverage copper’s ductility for dynamic electrical connections.

5. Conclusion

From safeguarding megawatt-scale substations with copper clad earth rods to enabling flawless copper-to-copper joints in aircon copper tube systems, the copper rod remains a cornerstone of advanced engineering. Its versatility across earthing, welding, and conductive applications—coupled with evolving material innovations like copper bonded steel—ensures its continued relevance in high-stakes technical environments. As global standards tighten and sustainability drives recycling, understanding the nuanced applications of rod copper and related forms becomes essential for engineers and procurement specialists alike.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Why. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.