1. Introduction

Just 24 hours ago, a major solar farm in Texas reported a lightning-induced grid failure—traced back to inadequate grounding. Engineers quickly identified that substandard earthing rods failed to dissipate the surge, causing costly downtime. This incident underscores a quiet but vital truth: not all grounding materials are created equal. Enter the humble yet high-performance copper rod.

While most people associate copper with wiring or plumbing, its role in niche industrial applications—especially in electrical safety and precision joining—is both sophisticated and indispensable. In this article, we’ll dive into two advanced uses of copper rod: as earthing rods in critical infrastructure and as specialized welding/brazing consumables in high-tech manufacturing.

2. Copper Rods in Electrical Earthing Systems

When it comes to protecting buildings, data centers, or wind turbines from electrical surges, the copper earth rod is the frontline defense. Unlike standard steel rods, a copper bonded earthing rod combines the strength of steel with the superior conductivity and corrosion resistance of copper.

These rods—also called copper clad ground rods or copper clad steel earth rods—are engineered by molecularly bonding a thick layer of pure copper onto a steel core. This hybrid design delivers the best of both worlds: mechanical durability for deep driving into rocky soil and long-term conductivity that outlasts bare steel by decades.

- Copper bonded steel rods typically feature 0.25mm or thicker copper cladding

- They’re widely used in telecom towers, substations, and EV charging stations

- The earthing rod price varies by length and cladding thickness, but performance justifies the cost in high-risk zones

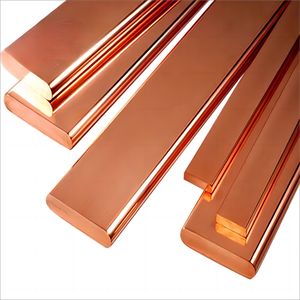

For ultra-corrosive environments like coastal installations, solid copper rods (sometimes called round bar copper or copper round bar) are preferred despite higher copper rod price. Their 100% copper composition ensures zero galvanic corrosion—critical for facilities where maintenance access is limited.

3. Precision Joining: Copper Rods in Welding and Brazing

Beyond grounding, copper rods play a starring role in metal joining—especially where thermal conductivity and non-sparking properties matter. In aerospace and electronics manufacturing, copper to copper brazing rods are essential for assembling heat exchangers, waveguides, and cryogenic systems.

Unlike steel welding, copper welding rod applications require precise control. Copper’s high thermal conductivity means it dissipates heat rapidly, demanding specialized techniques. That’s why professionals often use copper brazing rod alloys with phosphorus or silver to lower melting points and improve flow.

Common variants include:

- Copper to copper welding rod: for seamless joints in pure copper assemblies

- Welding rod copper with deoxidizers: prevents porosity during copper rod welding

- Copper alloy strip or beryllium copper strip: used when spring properties or strength are needed alongside conductivity

Interestingly, many confuse copper rods with copper strip or flat copper strip. While strips (like 1mm copper strip or nickel plated copper strip) are used in busbars or EMI shielding, rods are shaped for feeding into torches or driving into earth—each form optimized for its function.

4. Market Considerations and Material Choices

With copper prices fluctuating, buyers often weigh cost versus longevity. A copper bonded ground rod may cost less than a solid copper earth rod, but in saline soils, the latter could save replacement costs over 30+ years.

Similarly, when sourcing copper rod for welding, purity matters. Impurities can cause cracks or weak joints—so reputable suppliers specify oxygen-free or electrolytic-tough-pitch (ETP) grades.

For recyclers, stripping copper wire remains popular, but burning copper wire for scrap is discouraged—it releases toxic fumes and degrades metal value. The best way to strip copper wire is mechanical, preserving the copper strip wire for resale.

Meanwhile, copper strip price and copper rod price often move in tandem with LME (London Metal Exchange) trends. Those searching for ‘copper strip near me’ or ‘copper bars for sale’ should verify whether they need solid copper, copper clad, or alloyed forms—each serves distinct niches.

5. Conclusion

From shielding a Texas solar array from lightning to enabling leak-proof joints in satellite components, the copper rod proves its worth far beyond household plumbing. Whether deployed as a copper earth rod in a substation or as a copper brazing rod in a cleanroom, its blend of conductivity, durability, and versatility makes it irreplaceable in advanced engineering. As infrastructure demands grow more complex, so too does our reliance on this unassuming—but extraordinary—metal form.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Why. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.