1. Introduction

Just 24 hours ago, a major tech campus in Texas reported a near-total server outage due to a lightning-induced grounding failure—a stark reminder of how critical proper earthing is in high-stakes environments. The root cause? Inferior grounding materials that corroded within two years. This incident has reignited industry focus on reliable earthing components, especially the humble yet indispensable copper rod.

While most people associate copper with wiring or plumbing, its role as an earthing conductor—particularly in the form of copper earth rods—is foundational to electrical safety and system integrity. In this article, we’ll dive into why copper rods are the gold standard in advanced earthing applications, what types are best suited for specific environments, and how pricing and material innovations (like copper bonded steel) are shaping today’s market.

2. The Role of Copper Rods in Modern Earthing Systems

In electrical engineering, an earthing (or grounding) system safely directs fault currents and lightning strikes into the earth, protecting both equipment and human life. At the heart of these systems lies the ground rod—often made from solid copper or copper-clad materials.

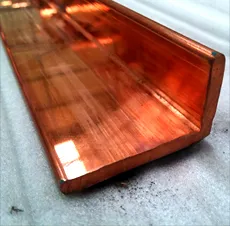

Pure copper rods, also known as rod copper or round bar copper, offer excellent conductivity and corrosion resistance, making them ideal for highly corrosive soils or coastal areas. However, due to cost, many engineers now opt for copper bonded earthing rods—steel cores electroplated with a thick layer of copper. These combine the tensile strength of steel with the conductivity and corrosion resistance of copper.

- Copper bonded ground rod: ideal for rocky terrain where driving depth matters

- Solid copper earth rod: preferred in chemical plants or marine environments

- Copper clad steel earth rod: balances cost, durability, and performance

3. Why Copper? Performance Advantages Over Alternatives

Copper’s electrical conductivity is second only to silver among common metals, but unlike silver, it’s affordable and widely available. When used as an earthing rod copper, it ensures low-resistance paths to ground—even over decades of service.

Compared to galvanized steel rods, copper rods last significantly longer. A typical copper bonded steel rod can endure 25–40 years in most soils, while pure copper may exceed 50 years. This longevity reduces maintenance costs and prevents catastrophic failures like the one in Texas.

Moreover, copper doesn’t degrade when exposed to moisture or common soil chemicals. Its oxide layer actually protects the underlying metal—unlike iron-based alternatives that rust and increase resistance over time.

4. Beyond Earthing: Other Niche Uses of Copper Rods

While earthing dominates industrial demand, copper rods serve other specialized roles. For instance, copper brazing rod and copper welding rod are essential in HVAC and refrigeration work, especially when joining aircon copper pipe sections without compromising thermal efficiency.

Technicians performing copper to copper brazing often rely on copper to copper brazing rods for seamless joints in high-pressure AC copper lines. Similarly, copper rod for welding is used in electrical busbar fabrication, where conductivity and joint integrity are non-negotiable.

In manufacturing, thin copper strips—sometimes cut from copper round bar stock—are used as flexible connectors in switchgear. Beryllium copper strip and nickel plated copper strip variants offer enhanced spring properties or corrosion resistance for aerospace and defense applications.

5. Market Trends: Pricing, Availability, and Material Choices

As of this week, copper rod price has seen modest volatility due to global supply chain adjustments and rising demand from renewable energy projects. Solar farms and EV charging stations require extensive grounding networks, driving up orders for copper bonded earthing rods and copper clad ground rods.

Buyers searching for ‘earthing rod price’ or ‘copper strip price’ will notice regional differences—urban suppliers often list ‘copper strip near me’ options with same-day delivery, while bulk buyers negotiate based on LME copper benchmarks.

Recycling also plays a role: stripping copper wire for scrap remains popular, but burning copper wire for scrap is increasingly discouraged due to toxic fumes. Instead, professionals use mechanical strippers—the best way to strip copper cable cleanly and safely.

6. Installation Best Practices and Common Pitfalls

Installing a copper earth rod isn’t just about hammering it into the ground. Soil resistivity testing, proper bonding to the main grounding electrode, and using exothermic welding (not clamps) for permanent connections are all critical steps.

Avoid mixing materials—connecting aluminum conductors directly to a copper earth strip can cause galvanic corrosion. Always use listed transition fittings or bimetallic connectors.

For data centers and telecom sites, specifications often call for copper earth strip 25x3mm or larger, ensuring minimal impedance during surge events. Flat copper strip or copper metal strips are also used along cable trays for equipotential bonding.

7. Conclusion

From preventing server meltdowns to enabling safe operation of air conditioning copper pipe systems, copper rods—whether solid, bonded, or clad—play an outsized role in modern infrastructure. Their unmatched blend of conductivity, durability, and versatility makes them irreplaceable in high-reliability applications. As electrification accelerates worldwide, demand for quality copper rod solutions will only grow, reinforcing copper’s status not just as a commodity, but as a cornerstone of electrical safety.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Why. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.