Title: What Type of Copper Pipe for Freon? A Story-Like Exploration

(What Type Of Copper Pipe For Freon)

Freon is one of the most commonly used refrigerants in the world today. It plays a crucial role in helping to keep our food, beverages, and other items warm, while also reducing their energy consumption. However, what type of copper pipe should we use for Freon depending on its specific application?

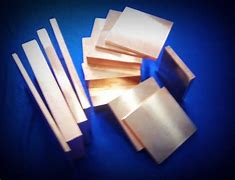

One of the most common ways that copper pipes are used for refrigerants is by using them as heat exchangers. Heat exchangers allow the temperature of hot air to be transferred from one location to another, without leaving any residue or particles behind. This is particularly useful when working with Freon systems that have very high temperatures, such as those found in large refrigerators.

However, there are some variations to the copper pipe that may not work as well for Freon applications. For example, some types of copper pipes may not be able to withstand the high temperatures that Freon can experience, which could lead to damage to the pipes or even failure. Additionally, some types of copper pipes may have a more aggressive tendency towards corrosion than others, which could result in longer service times and increased costs.

In addition to heat exchangers, other methods of conveying Freon include water transfer units (WTUs) and vapor units (VUS). These devices allow gases and liquids to be transferred through pipes, rather than being forced through the gas or liquid itself. This can be especially useful when working with systems that require significant changes in temperature or pressure, such as in refrigeration or engineering.

(What Type Of Copper Pipe For Freon)

Overall, there are many different ways that copper pipes can be used for Freon applications, and the choice ultimately depends on the specific needs and requirements of the system. It’s important to carefully consider the factors that affect the performance and reliability of the copper pipe before choosing it, including its resistance to temperature,, and corrosion. By following these best practices, you can ensure that your Freon system is reliable, efficient, and cost-effective.