In the ruthless search for commercial excellence and technology, the selection of the right product is not just a choice– it’s a vital tactical decision. Amongst the pantheon of design products, copper stands as a titan, and its extruded kind, Copper Extrusions, represents a pinnacle of flexibility and efficiency. These elements, formed with accuracy through the extrusion process, are the unrecognized heroes in many applications that power our contemporary globe. This short article explores the extensive and multifaceted properties of Copper Extrusions, studying their electrical, thermal, and rust resistance features to highlight why they are an indispensable resource for engineers and designers worldwide.

1. The Constitution of Copper Extrusions

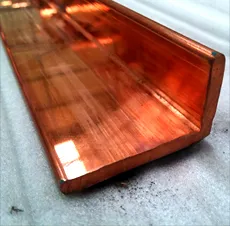

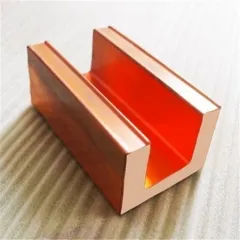

The genesis of a Copper Extrusion lies in its fundamental constitution. At its heart, it is pure or alloyed copper, shaped with a powerful manufacturing process referred to as extrusion. This procedure entails forcing a warmed, solid copper billet through a die of a particular cross-sectional profile under immense stress. The result is a constant size of material– a Copper Extrusion– that perfectly mirrors the intricate form of the die.

The material pedigree is extremely important. While C11000 (Electrolytic Tough Pitch Copper) is common for its superb electric conductivity, various other alloys like C12200 (Phosphorus Deoxidized Copper) offer enhanced weldability and resistance to embrittlement, and brass (copper-zinc) or bronze (copper-tin) alloys offer premium toughness and machinability for details applications. This foundational composition, integrated with the transformative extrusion procedure, bestows upon Copper Extrusions a special set of intrinsic properties that we will discover to be extensive. It is this very constitution that forms the bedrock of their succeeding, amazing qualities.

2. The Quintessential Features of Copper Extrusions

The superiority of Copper Extrusions in demanding environments is not accidental; it is the direct outcome of a constellation of exceptional buildings. These can be extensively classified into their integral physical qualities and their resulting useful capabilities.

2.1 What are the Intrinsic Physical Characteristics?

The physical residential properties of Copper Extrusions are the untainted, inherent high qualities bestowed by their atomic framework and important nature.

Unmatched Electric Conductivity: Copper is the nonpareil conductor amongst common design steels, second only to silver. Copper Extrusions inherit this stunning characteristic, using exceptionally reduced electric resistivity. This makes them the absolute frontrunners for conducting power with marginal energy loss, an important factor in an era obsessed with performance.

Leading Thermal Conductivity: The same free-flowing electrons that promote electrical conduction additionally make Copper Extrusions a thermodynamic virtuoso. They possess one of the highest thermal conductivity ratings, enabling them to move heat with an impressive rate and effectiveness. This home is the cornerstone of their usage in warmth exchangers and cooling systems.

Formidable Corrosion Resistance: Copper shows a resolute spirit against rust. When exposed to the atmosphere, it forms a stable, adherent layer of aging (such as copper carbonate) that works as a safety guard, halting further deterioration. This integral passivation supplies impressive resistance to atmospheric deterioration, drinkable water, and a vast array of chemicals, ensuring long-term stability and reliability.

Innate Antimicrobial Efficiency: An exceptional and typically underappreciated physical building is copper’s fundamental oligodynamic effect. Copper ions are lethally toxic to bacteria, viruses, and fungi, causing quick cell devastation on contact. This makes Copper Extrusions a greatly sanitary choice for surfaces in healthcare and food processing.

| Parameter | Typical Value / Range | Test Standard |

| Density | 8.89 – 8.94 g/cm³ | ASTM B193 |

| Melting Point | 1082°C (1980°F) | – |

| Electrical Conductivity | 85% – 101% IACS (Grade Dependent) | ASTM B193 |

| Thermal Conductivity | 200 – 390 W/m·K (Grade Dependent) | ASTM E1225 |

| Tensile Strength | 200 – 550 MPa | ASTM E8 / E8M |

| Yield Strength (0.2% Offset) | 150 – 500 MPa | ASTM E8 / E8M |

| Elongation (in 2″) | 15% – 45% | ASTM E8 / E8M |

| Hardness (Rockwell F / B) | 40 HRF – 85 HRB | ASTM E18 |

| Modulus of Elasticity | 110 – 120 GPa | – |

2.2 What are the Essential Functional Features?

Practical residential or commercial properties are the sensible, performance-oriented benefits that originate from the physical features, magnified by the extrusion procedure itself.

Design Unfettered by Complexity: The extrusion process is a tour de force of making flexibility. It permits the creation of very complicated, personalized profiles that would be much too costly or impossible to achieve with other techniques like rolling or machining. This allows designers to settle numerous parts right into a solitary, multifunctional extrusion.

Superlative Formability and Joinability: Despite their toughness, Copper Extrusions preserve superb ductility and pliability. They can be readily curved, stamped, or developed post-extrusion without compromising their stability. Moreover, they can be joined with ease, making use of a variety of techniques, consisting of soldering, brazing, and welding, assisting in durable and permanent settings.

Remarkable Surface Area End Up and Appearances: The as-extruded surface area is generally smooth and uniform, offering an excellent base for a range of coatings– from brightened and buffed to a fantastic radiance, to painted, plated, or chemically treated for certain shades and boosted security. The innate, cozy hue of copper also provides classic aesthetic allure.

3. The Qualities and Bad Marks of Copper Extrusions

A holistic understanding necessitates a balanced view, recognizing both the refulgent benefits and the pragmatic constraints.

3.1 What are the Unassailable Advantages?

The advantages of Copper Extrusions are so compelling that they typically overshadow the considerations of expense.

A Paragon of Effectiveness: Their mix of ultimate electric and thermal conductivity makes them the ultimate product for energy transmission and thermal management, causing systems that are extra powerful, portable, and energy-efficient.

A Treasure of Resilience: The exceptional corrosion resistance and inherent strength grant Copper Extrusions a remarkably long life span, often covering decades. This converts to reduced upkeep, replacement costs, and a reduced total price of ownership over the ownership’s life span.

A Stronghold of Public Health: The proven antimicrobial home is an effective, easy defense reaction versus the spread of pathogens, adding an important layer of safety and security in public rooms, healthcare facilities, and food preparation areas.

100% Recyclability without Deterioration: Copper is a continuous product. It can be recycled infinitely with no loss of its original properties. This makes Copper Extrusions a greatly lasting choice, aligning completely with the concepts of the circular economy.

3.2 What are the Pragmatic Drawbacks?

While awesome, Copper Extrusions are not a cure-all for all engineering obstacles.

Cost Price: The key restraint is the fairly high preliminary product price compared to alternatives like lightweight aluminum or steel. The raw copper material and the energy-intensive extrusion procedure contribute to a higher ahead of time investment.

Comparative Softness and Sensitivity to Use: Pure copper is softer than numerous steels and some lightweight aluminum alloys, making it much more vulnerable to rough wear and galling (sticky wear) in particular mechanical applications.

Substantial Weight: Copper’s high thickness indicates that Copper Extrusions are heavier than aluminum, which accounts for similar dimensions, which can be an important disadvantage in weight-sensitive applications like aerospace.

Sensitivity to Creep at Raised Temperatures: While exceptional at modest temperature levels, copper can soften and undertake creep (sluggish, permanent contortion under tension) at sustained heats, which should be very carefully considered in high-heat applications.

4. What are the Large Application Domain Names for Copper Extrusions?

The one-of-a-kind property profile of Copper Extrusions makes them the product of choice across a breathtakingly varied spectrum of industries.

Electrical Power & Transmission: The undisputed backbone of the worldwide electrical grid. Used in busbars, high-voltage switchgear, transformer windings, and electrical get in touches with as a result of their unrivaled conductivity.

Electronic devices & Telecoms: As warmth sinks in CPUs, GPUs, and power electronics, they manage the tremendous thermal loads of contemporary devices. They are likewise important in waveguides and shielding parts for RF communication.

Heating, Ventilation, & Air Conditioning (HVAC&R): The excellent product for heat exchanger tubes in condensers, evaporators, and radiators, where reliable warm transfer and corrosion resistance to refrigerants and water are vital.

Design & Building: Utilized in roof, cladding, gutters, and downspouts for their longevity, corrosion resistance, and stunning, advancing aging. Likewise made use of for antimicrobial door manages and barriers.

Renewable Energy Systems: Essential in solar thermal collectors for absorbing and transferring warm, and as extremely reliable busbars within solar photovoltaic panels and inverter systems.

Industrial Machinery & Automotive: Made use of in welding nozzles, resistance welding electrodes, and different bushings and bearings. In electric cars, they are important for battery busbars and power distribution devices.

Marine & Offshore Design: Their excellent resistance to deep-sea corrosion makes them suitable for condenser and heat exchanger tubes in ships and offshore systems.

5. What are the Powerful Technical Supremacies of Copper Extrusions?

Beyond the fundamental buildings, it is the collaborating technical preeminence of Copper Extrusions that solidifies their position as a premium design solution.

Unsurpassed Harmony of Conductivities: Nothing else material offers such a powerful mix of the highest electric and thermal conductivity in a single, conveniently formable package. This synergistic impact is irreplaceable in applications like high-power electric systems, where effective existing transportation and warmth dissipation are co-dependent demands.

Precision and Uniformity at Scale: The modern extrusion process, often combined with CNC machining, enables the production of components with extremely tight tolerances and flawless dimensional uniformity across high-volume production runs. This integrity is non-negotiable in automatic assembly lines.

Boosted Mechanical Characteristics through Alloying and Job Solidifying: The mechanical limitations of pure copper can be strategically overcome. Alloying with components like beryllium (for stamina) or chromium (for strength and conductivity retention at high temperatures) produces superalloys. Additionally, the extrusion procedure itself can induce job solidifying, raising the toughness and solidity of the final profile.

A Lead of Sustainability: The technical advantage reaches lifecycle efficiency. The 100% recyclability, coupled with the lengthy service life and energy efficiency they make possible in end products, positions Copper Extrusions as a technologically advanced service for a lasting future. Their use directly contributes to lowering the carbon impact of the systems they are incorporated into.

To conclude, Copper Extrusions are far more than simple steel forms. They are a testament to product scientific research excellence, providing an undisputable combination of electric prowess, thermal proficiency, and sustained rust resistance. By recognizing their extensive buildings and critical advantages, you can harness their complete capacity to introduce, maximize, and future-proof your most important applications.

About CopperGroup

CopperGroup is a trusted global Copper Extrusions supplier & manufacturer with over 12 years experience in providing super high-quality copper and relative materials. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, CopperGroup dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for Copper Extrusions, please feel free to contact us.

Tags:copper extrusions,extruded copper profiles,copper extrusion companies