1. Introduction

Just 24 hours ago, a major hyperscaler announced a $5 billion expansion of its AI-focused data center campus in Texas—highlighting an urgent need for ultra-reliable electrical grounding systems capable of handling massive power loads and lightning-induced surges. In this high-stakes environment, one unsung hero stands out: the copper rod.

While most people associate copper with wiring or plumbing, specialized forms like the copper earth rod, copper bonded ground rod, and copper clad steel earth rod play a pivotal role in protecting billion-dollar server farms from catastrophic electrical faults. Let’s dive into how these niche copper products keep our digital world running safely.

2. Why Copper Rods Dominate Modern Earthing Systems

Copper’s unmatched electrical conductivity (second only to silver) and natural corrosion resistance make it ideal for grounding applications. But not all copper rods are created equal—engineers must choose between solid copper, copper bonded, or copper clad variants based on soil conditions, budget, and longevity requirements.

- Solid copper rod: Offers maximum conductivity and lifespan but comes at a premium price (copper rod price can exceed $15 per linear foot).

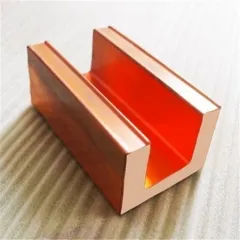

- Copper bonded earthing rod: Features a steel core electroplated with thick copper (typically 0.25mm+), balancing strength and conductivity at lower cost.

- Copper clad steel ground rod: Uses metallurgically bonded copper over high-tensile steel—ideal for rocky soils where driving depth matters.

For mission-critical facilities like data centers, copper bonded ground rods and copper clad earth rods are increasingly favored due to their durability and cost-effectiveness without sacrificing performance.

3. Real-World Application: Grounding AI Data Centers

Modern AI data centers draw tens of megawatts of power and house sensitive equipment vulnerable to even microsecond voltage spikes. A single lightning strike or grid fault can fry servers if grounding fails.

Here’s where earthing rod copper shines. Engineers install arrays of copper earth rods—often 8 to 10 feet deep—connected via flat copper strip conductors (like 25x3mm copper earth strip) to create a low-resistance earth mat beneath the facility. This system safely dissipates fault currents into the ground.

The copper strip for earthing is typically tinned or bare, depending on environmental exposure. For indoor risers, flexible copper bus bar or nickel plated copper strip may be used to link panels while accommodating thermal expansion.

4. Material Selection: Beyond the Basic Rod

Choosing the right grounding material isn’t just about the rod—it’s about the entire conductor ecosystem. While the copper rod serves as the vertical electrode, horizontal connections often use flat copper metal strips.

Popular options include:

- Thin copper strips (e.g., 1mm copper strip) for tight enclosures

- Beryllium copper strip for high-strength, non-sparking zones

- Copper strip roll for continuous runs along cable trays

- Copper edging strip to protect insulation edges near busbars

Note: Avoid burning copper wire for scrap—a common but hazardous practice that releases toxic fumes. Instead, use mechanical strippers for stripping copper wire cleanly when recycling offcuts.

5. Cost Considerations and Sourcing

Budget plays a key role in material selection. While solid round bar copper offers top-tier performance, many projects opt for copper bonded steel to reduce costs. Current earthing rod price benchmarks show copper bonded variants costing 30–50% less than pure copper rods.

When sourcing, look for certified suppliers offering copper clad steel earth rod with ASTM or IEC compliance. Search terms like ‘copper strip near me’ or ‘copper bars for sale’ can help locate local distributors—but always verify conductivity specs and plating thickness.

Also, don’t confuse copper strip with copper stip or misspellings like ‘opper pipework’—precision matters when ordering technical materials.

6. Installation Best Practices

Proper installation ensures your copper rod system performs as designed:

- Drive rods vertically using a hydraulic driver to avoid bending.

- Connect rods to copper strip using exothermic welding or listed compression fittings—never rely solely on clamps in corrosive soils.

- Test earth resistance post-installation; values should be under 5 ohms for data centers.

- Use copper to copper brazing rods or copper welding rod for permanent joints where solder won’t suffice. Copper rod for welding must match base metal composition to prevent galvanic corrosion.

Remember: copper rod welding requires preheating and proper filler—copper to copper welding rod ensures metallurgical compatibility.

7. Conclusion

From AI data hubs to telecom shelters, the humble copper rod—whether as a solid earthing rod copper, copper bonded ground rod, or part of a flat copper strip network—remains foundational to electrical safety. As infrastructure demands grow, so does the need for smart, code-compliant grounding using high-performance copper products. Whether you’re comparing copper rod price or sourcing a roll of copper strip, prioritize quality over shortcuts—your uptime depends on it.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Use. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.