Under the humming surface area of our contemporary world, within the heart of towering power circulation systems and the detailed makeup of innovative equipment, exists an unhonored hero: the Copper Bar. Much more than a simple strip of metal, this basic part serves as the genuine lifeline and backbone of industrial may. Its unmatched mix of intrinsic residential or commercial properties makes it an important force in applications where integrity, performance, and safety are definitely nonnegotiable. For designers, job managers, and international purchase professionals, an extensive understanding of copper bars is not just academic– it is a calculated necessary for maximizing efficiency, ensuring operational stability, and forging a resilient supply chain. This thorough analysis looks into the very significance of copper bars, unraveling their features, advantages, constraints, and their significant role in sustaining the important infrastructure that powers our people.

1. Copper Bar: The Perfect Industrial Channel

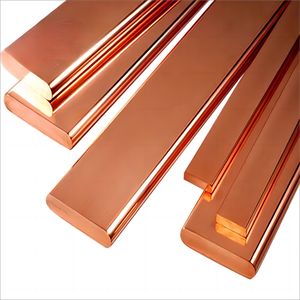

A Copper Bar is a strong, rectangular-shaped or square-shaped profile made from high-purity copper or its alloys. It is engineered to function as a durable and highly effective pathway for the transportation of electrical power, rather than the more flexible, insulated nature of electrical cords. Think about it as the industrial-grade superhighway for electrical existing, made to deal with enormous power flows that would certainly bewilder standard cabling.

These bars are produced via a careful process of constant spreading and warm rolling, followed by accuracy illustration or extrusion to attain exact dimensional tolerances and a premium surface area finish. They are readily available in different qualities, with C11000 (Electrolytic Challenging Pitch Copper) being one of the most common, popular for its extraordinary electrical conductivity. Their kind aspect is not arbitrary; the level, wide shape gives a big surface, which is extremely important for effective warm dissipation and safe, high-pressure connections in busbar systems. From the major power intake of a high-rise to the thick circuitry of a switchgear panel, the copper bar is the silent, unwavering workhorse that develops the core of electric circulation networks.

2. The Core Features of Copper Bars: A Makeup of Quality

The supremacy of copper bars in essential applications is not unintentional. It is the direct result of a superb harmony of physical and useful homes that are, in many ways, unparalleled by alternative materials.

2.1 The Undisputable Physical Expertise of Copper Bars

The physical attributes of copper bars are the foundation of their fabulous efficiency. Foremost is their peerless electrical conductivity. With a ranking of 100% IACS (Worldwide Annealed Copper Criterion), pure copper sets the global benchmark for reliable present circulation, decreasing resisting energy losses as heat. This is matched by its powerful thermal conductivity, matched just by silver, which allows it to quickly dissipate the warmth generated by present circulation, preventing hazardous thermal accumulation.

Additionally, copper bars show exceptional ductility and pliability. They can be bent, developed, and shaped with relative ease without fracturing, enabling custom arrangements to fit complex busbar assemblies. Their excellent tensile stamina and superb tiredness resistance guarantee they keep structural stability under mechanical tension and vibrational forces, providing long-term reliability. The inherent corrosion resistance of copper, forming a safety patina layer when exposed to the environment, guarantees a long and serviceable life expectancy even in tough settings.

2.2 The Huge Practical Supremacy of Copper Bars

Beyond their natural physical characteristics, the functional abilities of copper bars are what absolutely solidify their necessity. Their main feature is to create a low impedance, high current backbone for electrical systems. This enables the secure and reliable circulation of thousands of amperes from a solitary resource to numerous tons, a job for which a nest of specific cables would be unwise and unsafe.

The layout of copper bars promotes easy and protected connections. They can be precision-drilled and touched to fit numerous bolted links, guaranteeing steady, low-resistance joints that are important for system security and performance. This modularity streamlines installation, maintenance, and future system developments. Another extensive functional benefit is their electromagnetic compatibility. The strong, foreseeable geometry of copper bars aids in taking care of magnetic fields, minimizing reactance and minimizing disturbance with delicate neighboring electronics. Lastly, their nonmagnetic nature is an important property in applications like MRI devices and precision clinical instruments, where any kind of magnetic disturbance would certainly be devastating.

3. The Intrinsic Benefits and Negative Aspects of Copper Bars

A practical assessment demands a clear-eyed sight of both the frustrating strengths and the tangible constraints of copper bars.

3.1 The Engaging and Frustrating Advantages

The benefits of specifying copper bars are extensive and diverse. Their unmatched electrical effectiveness translates directly into lower operational costs over the system’s lifetime, as less power is thrown away as heat. This also adds to a smaller carbon footprint, aligning with worldwide sustainability goals. The toughness and epic longevity of copper bars suggest that when mounted, a busbar system can outlive the equipment it offers, giving a phenomenal roi and decreasing the total cost of ownership.

From a safety perspective, their high melting point (1085 ° C) and remarkable short-circuit withstand capability are important. In case of a mistake, a copper bar can endure the substantial thermal and magnetic tensions long enough for safety breakers to operate, avoiding catastrophic failing. Moreover, the 100% recyclability of copper without any degradation in performance makes it a supremely eco-friendly selection, shutting the material loophole and giving substantial economic value at the end of its service life.

3.2 The Practical Recommendation of Drawbacks

Regardless of their outstanding qualities, copper bars are not without their difficulties. One of the most obvious is the higher first material expense compared to aluminum, their main rival. This upfront financial investment can be a substantial consideration for budget-conscious projects. An additional factor to consider is their substantial weight; copper is a dense metal, and big busbar systems can be really heavy, possibly affecting structural assistance demands in some layouts.

Copper is additionally at risk of galvanic deterioration when directly linked to certain different steels (like aluminum or steel) in the presence of an electrolyte. This requires the use of effectively ranked bimetallic ports or safety finishings to alleviate the danger. Lastly, in its stiff state, pure copper is relatively soft, making it vulnerable to slip– a slow-moving, long-term deformation under continuous mechanical pressure from bolted joints– which should be made up in the torque specs and joint style to preserve link stability over decades of service.

4. Deconstructing the Application of Copper Bars in Important Equipment and Structures

The academic superiority of copper bars ends up being absolutely lighting when checked out with the lens of their real-world applications. They are the quiet, steadfast guardians of our technical environment.

In Power Circulation Switchgear and Panelboards, copper bars form the main busbar that adjoins circuit breakers, switches, and meters. Their high current-carrying capability and architectural strength are necessary for managing the immense power streams within these enclosures, ensuring functional security and safety for personnel. Within Industrial Transformers, huge copper bar windings are used due to their high short-circuit stamina and space-efficient design, allowing the effective stepping up and down of voltage degrees that develop the foundation of the electrical grid.

The world of Renewable resources is just as based on copper bars. In solar energy inverters and wind generator nacelles, they are employed to manage the high DC and air conditioner currents, where their dependability and efficiency are essential for optimizing energy yield. The Transport Sector relies on copper bars in the grip power systems of electric trains and trams, and within the charging facilities for electrical vehicles, where they manage the speedy transfer of high-power electrical power.

Probably most noticeably, in high-rise buildings and Data Centers, copper bars are the undisputed champion for increasing major busways and critical power circulation. Their portable power thickness enables even more existing to be brought in a smaller area compared to cables, a critical benefit in space-constrained upright structures. Their superior resistance to fire and arc flash, compared to polymer-insulated cables, offers an additional layer of life security in these densely inhabited and asset-critical atmospheres. From the substation to the web server rack, the copper bar confirms itself, time after time, as the essential foundation of the modern market.

About CopperGroup

CopperGroup is a trusted global Copper Bars supplier & manufacturer with over 12 years experience in providing super high-quality copper and relative materials. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, CopperGroup dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for Copper Bars, please feel free to contact us.

Tags:copper bars,ground bus bar,copper flat bar