Product Categories

- Copper Plate (888)

- Copper Pipe (922)

- Copper Rod (893)

- Copper wire/Copper stranded wire/Braided wire (535)

- Copper Bar (649)

- Copper Materials/Products (2)

- Copper Strip (904)

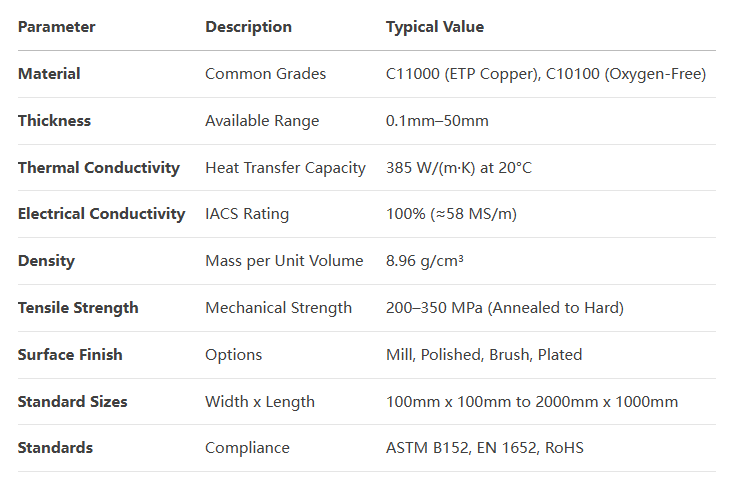

Copper plates are flat, thin sheets of copper that find application in industries ranging from electrical engineering and construction to sculpture and cookware. Key parameters defining their characteristics and usability are:

Elongation: Elongation at break indicates the ductility of the copper plate, or how much it can stretch before breaking, which is crucial for forming operations.

copper plate

High thermal conductivity: The excellent thermal conductivity of copper makes it an ideal material for radiators and heat exchange equipment.

Corrosion resistance: Strong anti-oxidation ability, suitable for high temperature, humid or chemical environment.

Electromagnetic shielding: It can effectively shield electromagnetic interference (EMI) and is suitable for electronic equipment protection.

Easy to process: It can be stamped, cut, and polished to meet different industrial needs.

Beautiful and durable: The surface can be plated or polished, which is both functional and decorative.

Electronic heat dissipation: CPU heat sink, LED substrate, power module cooling.

Industrial equipment: Vacuum coating target, electrode, bearing gasket.

Electromagnetic shielding: Electronic instrument housing, communication equipment shielding cover.

Decoration and art: relief, medals, crafts.

Food processing: baking molds, chocolate making tools (food grade copper).

Copper-group is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality copper and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality copper products, please feel free to contact us or click on the needed products to send an inquiry.

L/C, T/T, Western Union, Paypal, Credit Card etc.

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

Is copper plate suitable for high-frequency circuit applications?

Yes, high-purity oxygen-free copper (such as C10100) can reduce signal loss.

How to prevent the copper plate from oxidizing and turning black?

Store in a dry environment, or perform electroplating (such as nickel plating, tin plating).

Which is better in terms of heat dissipation performance, copper plate or aluminum plate?

Copper conducts heat faster (385 W/m·K vs aluminum 237 W/m·K), but aluminum is lighter and has a lower cost.

Can copper plates be used for food contact?

Food-grade copper (such as C11000) must be used and meet FDA/EC standards.

How to choose the thickness of the copper plate?

Depends on the application: 0.5–3mm is commonly used for heat sinks, and thicker (5–10mm) is required for structural parts.Characteristics and advantages of copper plate