-

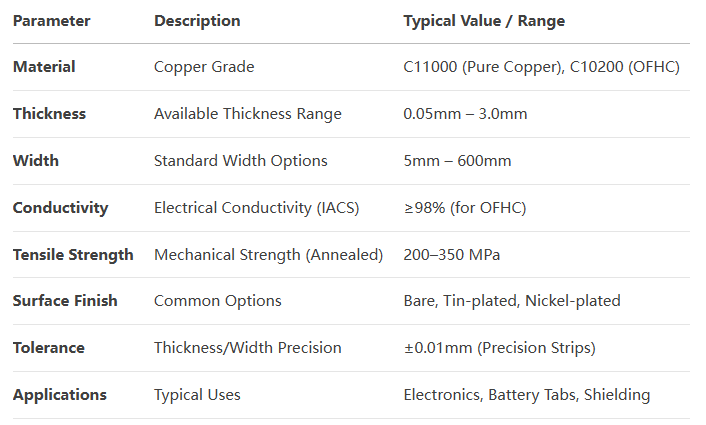

Copper Strip

Durable Flat Copper Strip s Direct ing Small 99.95%

Product Categories

- Copper Plate (888)

- Copper Pipe (922)

- Copper Rod (893)

- Copper wire/Copper stranded wire/Braided wire (535)

- Copper Bar (649)

- Copper Materials/Products (2)

- Copper Strip (904)