Overview of copper rod

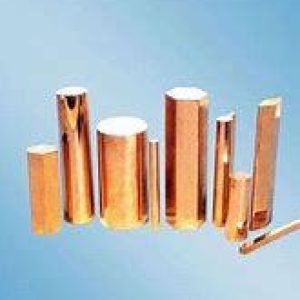

- Diameter: This refers to the cross-sectional size of the rod. Copper rods can vary in diameter from very thin (measured in millimeters) for precision applications like electronics or wiring, to thicker sizes (measured in inches or centimeters) for industrial use, such as in construction or machinery parts. Common diameters might range from 1mm to several inches.

- Length: The length of a copper rod can greatly vary based on its intended use. It can be supplied in standard lengths (e.g., 3 meters, 6 meters) or custom-cut to specific requirements. Some suppliers offer rods in coils for continuous processing applications.

- Purity: Copper rods are available in different levels of purity, with the most common being electrolytic tough pitch (ETP) copper, which typically has a purity of 99.95% copper content. Higher purity copper (e.g., 99.99%) may be used for specific electrical applications where conductivity is paramount.

- Temper or Hardness: Copper rods can be supplied in various tempers, indicating their hardness and malleability. Annealed (soft) copper is more ductile and easier to form, whereas harder tempers (like half-hard or hard-drawn) offer greater strength and springiness, suitable for mechanical applications.

-

Conductivity: A crucial parameter for copper rods used in electrical applications, conductivity measures how well the material allows electric current to flow. Copper’s high conductivity makes it ideal for wiring and other electrical components. Conductivity is usually expressed as a percentage of IACS (International Annealed Copper Standard).

- Surface Finish: This can range from a smooth, bright finish for aesthetic or precision applications to a rougher, matte finish for uses where appearance is less critical. Oxidation-resistant coatings may also be applied to protect the copper during storage or transportation.

- Tensile Strength: This measures the maximum stress that the copper rod can withstand before it fractures. It’s an important factor in determining its suitability for applications requiring mechanical strength.

- Elongation: Elongation at break refers to the percentage increase in length a copper rod can undergo before it breaks under tension. It indicates the material’s ductility.

-

Resistivity: The reciprocal of conductivity, resistivity measures the resistance of a material to electrical current flow. For copper, this value is typically low, reflecting its high conductivity.

copper rod

Characteristics and advantages of copper rods

High conductivity: Copper’s electrical conductivity is second only to silver, and it is suitable for high-precision electrical components.

Excellent thermal conductivity: Widely used in high-efficiency thermal conductivity scenarios such as heat dissipation components and heat exchangers.

Corrosion resistance: Good corrosion resistance to the atmosphere, water and non-oxidizing acids.

Excellent mechanical properties: Combining strength and ductility, easy to cut, forge and weld.

Environmentally friendly and recyclable: 100% recyclable, in line with sustainable development requirements.

Specifications of Copper Rod

Application of copper rods

Power industry: motor windings, switch contacts, grounding rods.

Industrial machinery: bearings, valves, hydraulic components.

Refrigeration equipment: air conditioning condenser tubes, refrigeration compressor parts.

Electronic field: connectors, semiconductor brackets.

Architecture and art: structural parts, decorative sculptures, hardware accessories.

Company Profile

Copper-group is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality copper and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality copper products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of copper rods

What is the difference between copper rods and copper tubes?

Copper rods are solid and suitable for load-bearing parts; copper tubes are hollow and are mostly used for fluid transmission.

What are the common alloy types of copper rods?

Brass rod (Cu-Zn), bronze rod (Cu-Sn), white copper rod (Cu-Ni), etc.

How to avoid surface oxidation and discoloration of copper rod?

Store in a dry environment, or apply antioxidant (such as BTA).

What should be paid attention to when cutting copper rod?

Use sharp tools, cut at low speed, and avoid sticking (cutting fluid can be added).

Can copper rods be used in the food industry?

Yes, but it must meet food grade standards (such as lead-free copper C10200).