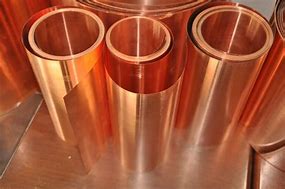

## Copper Pipe Blues? Banishing Ugly Green Starnish for Good!

(How To Fix Copper Pipe Corrosion)

You’ve seen it. That ugly, crusty green or blue gunk building up around your copper pipes, especially near joints or valves. It looks bad. It feels wrong. This is corrosion, and ignoring it invites bigger headaches. Water leaks, expensive damage, maybe even contaminated water. That green stuff means trouble. But don’t panic. Fixing corroded copper pipes is totally doable. Let’s tackle it.

It starts small. Copper naturally forms a protective skin, a patina. This is good. But sometimes, things go wrong. Bad water chemistry, like high acidity or minerals, eats away at the copper. Stray electrical currents zipping through your pipes (bad wiring can eat pipes!) speed things up. Poor installation, like flux left behind after soldering, creates weak spots. Even dissimilar metals touching, like steel fittings on copper pipe, spark a chemical reaction. The result? That nasty green surprise.

First, find the problem. Look everywhere pipes are visible: under sinks, in the basement, near the water heater. Check joints, fittings, valves, anywhere pipes connect. Look for green or blue crust, white powdery deposits, or damp spots. Feel for roughness. Pinpoint every bad spot.

Got your spots? Time to fix. Here’s how:

1. **Surface Scrub (Minor Trouble):** If the corrosion looks thin, just on the surface, you might get lucky. Turn off your water supply! Drain the pipes by opening faucets. Dry the area well. Grab fine steel wool or a special copper cleaning pad. Gently scrub the green stuff away. Don’t scratch the copper! Rinse the area thoroughly with clean water. Dry it completely. This is just for light surface stuff. Deep pits or leaks need more.

2. **Patch the Pinpoint Leak (Tiny Hole):** Found a tiny pinhole leak? You can try a temporary patch. Turn off the water. Drain the pipes. Dry the area completely. Get some epoxy putty made for plumbing. Knead it well until the colors mix. Smear a thick layer over the leak, covering a good inch around it. Press it hard. Let it cure completely, following the package time. Remember, this is a band-aid, not a cure. Plan for a real fix soon.

3. **Cut and Replace (The Sure Fix):** This is the best, most lasting solution. You cut out the bad section and put in fresh, clean pipe. Turn off the water. Drain the pipes. Mark the pipe at least an inch away from *each* end of the corrosion. Use a tube cutter for a clean, straight cut. Remove the damaged piece. Prep the ends of the existing pipe. Clean them bright and shiny inside and out with sandpaper or emery cloth. Measure carefully. Cut a new piece of copper pipe to fit. Clean its ends too. You’ll need two couplings (or a coupling and a fitting if replacing near a joint). Assemble everything dry first. Apply flux paste to the cleaned pipe ends *and* inside the fittings. Fit the new pipe and couplings together. Heat the joint evenly with a propane torch. Touch solder wire to the joint. It should melt and flow smoothly into the gap all around. Let it cool completely. Turn the water back on slowly. Check for leaks! This takes practice. If unsure, call a pro.

4. **Wrap It Up (Emergency Only):** Got a sudden leak spraying water? You need an emergency stopgap *fast*. Turn off the water main immediately! Dry the pipe as best you can. Grab a pipe repair clamp or even epoxy putty. Follow the clamp instructions tightly, or apply putty thickly over the leak. This is strictly temporary, buying you time for a proper repair. Don’t rely on it long-term.

Prevention beats repair. Check your pipes regularly. Look for that first hint of green. Fix small drips fast. Ensure your home’s electrical grounding is correct. Consider a water test if you suspect aggressive water. Use dielectric unions whenever connecting copper to different metals like steel or galvanized pipe. These special fittings stop the bad chemical reaction. When soldering, clean off all excess flux paste afterward. Plumber’s tape (Teflon tape) is your friend on threaded fittings, preventing leaks that start corrosion.

(How To Fix Copper Pipe Corrosion)

Time matters here. Spotting corrosion early makes fixes easier and cheaper. Don’t let the green gunk win. Identify the problem, choose the right fix, and get your pipes shining safely again.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)