1. Introduction

As of June 2024, global demand for high-conductivity copper materials has surged due to infrastructure upgrades in renewable energy and data center grounding systems. According to industry reports from the International Copper Association, prices for copper earth rods and copper strip products have seen a 7% increase over the past month, driven by supply chain adjustments and stricter conductivity standards in the EU and North America.

Copper rods are indispensable across electrical, construction, and manufacturing sectors—but choosing the right type and installing it correctly is critical for safety and performance. This guide walks you through selecting, installing, and maintaining various copper rod types, including copper earth rods, copper brazing rods, and copper round bars.

2. Understanding Types of Copper Rods

Not all copper rods serve the same purpose. Confusing a copper welding rod with a copper bonded ground rod can lead to system failure or safety hazards.

2.1. Earthing and Grounding Rods

For grounding systems, you’ll encounter several variants:

- Solid copper rod: Pure copper, highly corrosion-resistant, ideal for aggressive soil conditions.

- Copper bonded earthing rod: Steel core with a thick electrolytic copper layer (typically 0.25mm+). Offers strength and conductivity at lower cost.

- Copper clad steel ground rod: Similar to bonded but uses metallurgical bonding; slightly less conductive but still widely used.

Always verify compliance with IEEE 80 or IEC 62305 standards when purchasing an earthing rod copper product. Check the earthing rod price against longevity—cheap alternatives may degrade faster.

2.2. Welding and Brazing Rods

For joining copper components:

- Copper brazing rod and copper to copper brazing rods are used with flux and torches for HVAC or plumbing repairs.

- Copper welding rod (or copper to copper welding rod) is employed in TIG or MIG processes for industrial applications.

Never substitute aluminum or steel rods—use only welding rod copper designed for non-ferrous metals to avoid weak joints.

2.3. Structural and Conductive Rods

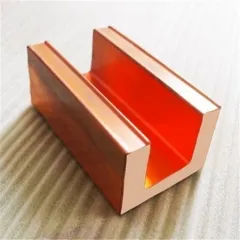

Copper round bar (also called rod copper or round bar copper) is used in busbars, machinery parts, and electrical connectors. Flexible copper bar variants serve dynamic current applications like switchgear.

3. Step-by-Step: Installing a Copper Earth Rod

3.1. Gather Materials

- Copper bonded ground rod (typically 16mm diameter × 2.4m length)

- Clamp connector (bronze or tinned copper)

- Bare copper conductor (e.g., #6 AWG)

- Driving tool or hammer drill

- Soil resistivity tester (optional but recommended)

3.2. Installation Process

Choose a location away from gas lines and building foundations. Drive the copper clad earth rod vertically into moist soil using a slide hammer—never bend it.

If soil is rocky, use multiple shorter copper clad steel earth rods spaced 6m apart and bonded together.

Attach the grounding conductor using an exothermic weld or listed mechanical clamp. Ensure no paint or coating interferes with contact.

Backfill with bentonite clay if soil resistivity exceeds 100 ohm-meters to enhance performance.

4. Maintaining and Troubleshooting Copper Rod Systems

4.1. Corrosion and Loosening

Inspect clamps annually for green patina or looseness. Replace copper bonded rods showing exposed steel core.

In coastal areas, prefer solid copper earth rods over copper bonded steel due to salt-induced corrosion.

4.2. Poor Ground Resistance

If resistance readings exceed 25 ohms, add parallel rods or use a copper strip for earthing to increase surface contact. A copper earth strip 25x3mm is often more effective in shallow trenches.

5. Working with Copper Strip and Wire

While not rods per se, copper strip products often complement rod-based systems.

Use flat copper strip or thin copper strips for grounding grids. For scrap recovery, the best way to strip copper wire is with a manual or automatic wire stripper—never burn copper wire for scrap, as it releases toxic fumes and devalues the metal.

When sourcing materials, search for ‘copper strip near me’ or ‘roll of copper strip’ from certified recyclers. Nickel plated copper strip offers enhanced solderability for electronics.

6. Pricing and Sourcing Tips

Copper rod price varies by purity, diameter, and market LME rates. As of mid-2024, expect $8–$12/kg for ETP-grade copper round bar.

Compare earthing rod price quotes that include certification—avoid uncertified ‘copper clad ground rod’ imports with thin plating.

For HVAC work, aircon copper pipe price and copper pipe fittings should be sourced together to ensure compatibility during copper pipe soldering.

7. Conclusion

Selecting and installing the correct copper rod—whether a copper earth rod, copper brazing rod, or copper round bar—requires attention to application, environment, and standards. By following these guidelines, you ensure system reliability, regulatory compliance, and long-term cost efficiency. Always prioritize certified materials and proper installation techniques over short-term savings.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as How. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.