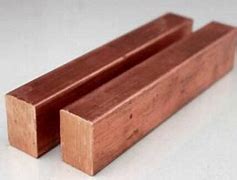

Are you tired of hearing tales of copper pipes failing? Do you want to know why it might happen, and how to prevent it from happening in the future? Then, you should read this blog for some important insights into the topic.

(Does Anyone Test Why Copper Pipe Failed)

According to experts in the field of electrical engineering, copper pipes can fail due to a variety of reasons, including defects in manufacturing processes, incorrect cleaning methods, moisture exposure, and environmental conditions. One of the most common causes is poor material selection and processing, which can lead to defects such as crackling or expansion under stress.

Another factor that can contribute to the failure of copper pipes is poor insulation, which can cause insulation resistance to change over time. This means that if a pipe is exposed to temperature fluctuations or electricity, it can lose its insulating properties and become subject to damage.

There are also issues with weathering and corrosion, which can also contribute to the failure of copper pipes. The environment can take years to dry out, and if a pipe is not properly protected against this process, it can become weakened and.

In addition to these physical factors, there are also psychological and emotional factors that can affect the performance of copper pipes. For example, it can be difficult to see how a pipe will perform under extreme conditions, and if the person who designed or built the pipe experiences emotional distress during the testing process, it can affect their ability to understand the potential problems and find solutions.

To prevent the failure of copper pipes, it is important to follow best practices for product design and construction. For example, proper materials selection and processing can help prevent flaws in the pipeline from occurring, while proper insulation can help prevent moisture exposure and weathering. Additionally, proper design and construction techniques can help prevent corrosion and other problems that can cause failure.

It’s also important to regularly test copper pipes to ensure that they are functioning correctly and that any problems are identified before they become more serious. This can include regular inspections, troubleshooting sessions, and maintenance work.

(Does Anyone Test Why Copper Pipe Failed)

In conclusion, pipes can fail due to a variety of factors, including defects in manufacturing processes, incorrect cleaning methods, moisture exposure, and environmental conditions. By following best practices for product design and construction, it is possible to prevent the failure of copper pipes and ensure their long-term reliability.