1. Introduction

In the past 48 hours, a major utility outage in Texas traced back to inadequate grounding infrastructure has reignited industry discussions about the importance of high-quality earthing materials—particularly copper rods. As climate-related electrical surges increase, engineers and contractors are reevaluating their choices between solid copper earth rods and cost-effective alternatives like copper bonded steel. This spotlight underscores how a seemingly simple component—the copper rod—plays a pivotal role in system safety and longevity.

While copper is widely known for plumbing and wiring, its use in specialized forms like copper rod for welding or copper earth rod installations reveals a deeper layer of engineering nuance. From substation grounding grids to precision HVAC repairs, the right copper rod can mean the difference between decades of service and premature failure.

2. Copper Rods in Electrical Earthing Systems

2.1. Solid Copper vs. Copper-Bonded Ground Rods

When it comes to earthing, not all rods are created equal. A pure copper earth rod offers superior corrosion resistance and electrical conductivity, making it ideal for harsh environments like coastal areas or chemical plants. However, its higher copper rod price often leads specifiers to consider copper bonded ground rods—steel cores electroplated with a thick layer of copper.

Copper bonded earthing rods (also called copper clad steel earth rods) provide a balance: nearly the conductivity of solid copper at a fraction of the cost. The copper bonded steel construction ensures mechanical strength while maintaining low-resistance grounding. For many commercial projects, this is the sweet spot—especially when budget constraints clash with safety codes.

2.2. Sizing and Installation Considerations

Common dimensions include 5/8″ diameter by 8–10 ft lengths, but custom copper round bar sizes are available for industrial substations. The copper earth strip 25x3mm price is also relevant when connecting multiple rods into a grid. Proper installation requires driving the earthing rod copper deep enough to reach moist soil layers, ensuring stable impedance year-round.

Contractors often search for ‘earthing rod price’ or ‘copper bonded ground rod near me’ when sourcing materials quickly. Yet, long-term performance hinges on correct material choice—not just upfront cost.

3. Copper Rods in Specialized Welding and Brazing

3.1. Copper to Copper Joining Techniques

HVAC technicians and refrigeration specialists frequently rely on copper rod welding for repairing aircon copper pipe systems. Unlike steel, copper’s high thermal conductivity demands precise heat control. Here, copper brazing rod or copper to copper brazing rods are preferred over traditional welding rods.

Copper welding rod formulations often include phosphorus or silver alloys to lower melting points and improve capillary flow during copper tube soldering. These rods—marketed as copper to copper welding rod or welding rod copper—are essential for leak-free joints in AC copper pipe networks, where even minor flaws can cause refrigerant loss.

3.2. Why Not Use Standard Steel Rods?

Attempting to weld copper with standard steel-based rods leads to brittle, high-resistance joints prone to cracking. Pure copper rod for welding ensures metallurgical compatibility. In fact, resoldering copper pipe without removing it often requires pre-tinned copper brazing rods that flow cleanly into tight spaces—a technique mastered by seasoned HVAC pros.

For those maintaining legacy systems, knowing the difference between copper pipe sizing (e.g., 15mm copper tube vs. 22mm copper pipe) and selecting the matching copper rod diameter is crucial for seamless repairs.

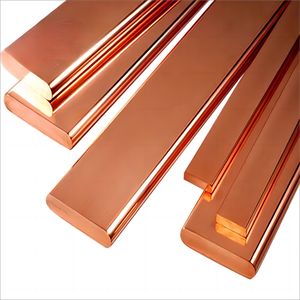

4. Beyond Rods: The Role of Copper Strips and Bars

While rods dominate earthing and welding, flat conductors like copper strip are gaining traction in grounding mats and busbar assemblies. Thin copper strips, beryllium copper strip, or nickel plated copper strip offer flexibility where rigid rods won’t fit. A copper strip for earthing might be used around sensitive telecom racks, while a flexible copper bus bar handles high-current distribution in data centers.

Scrap recyclers often ask about the best way to strip copper wire or stripping copper wire for scrap—but industrial users care more about performance specs. Whether it’s a 1mm copper strip roll or a heavy-duty copper flat bar, purity and temper matter. And yes, despite myths, burning copper wire for scrap is both illegal and environmentally harmful; mechanical stripping remains the fast way to strip copper wire safely.

5. Conclusion

From underground earthing grids to rooftop aircon copper tube repairs, the humble copper rod proves indispensable in high-stakes applications. Whether you choose solid rod copper for maximum longevity or copper clad steel ground rod for cost efficiency, understanding your environment and electrical demands is key. As infrastructure resilience becomes non-negotiable, investing in the right copper-based components isn’t just smart—it’s essential.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Copper. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.