1. Introduction

Just 24 hours ago, a major European data center operator reported a near-miss lightning strike that tested the limits of its grounding infrastructure. Thanks to a network of high-conductivity copper earth rods installed just months prior, zero downtime occurred—a testament to the unsung heroism of precision-engineered copper components. While copper pipe and wiring dominate headlines, it’s the humble copper rod that quietly enables resilience in everything from skyscrapers to spacecraft.

In this article, we’ll dive into two niche but vital applications of copper rod: advanced electrical earthing systems and specialized copper welding techniques. Far beyond basic plumbing or scrap value, today’s copper rod—whether solid, clad, or alloyed—delivers unmatched conductivity, corrosion resistance, and mechanical reliability where failure is not an option.

2. Copper Rod in High-Reliability Earthing Systems

Electrical safety in industrial and telecom facilities hinges on effective grounding. Here, the copper earth rod isn’t just a metal stick—it’s a lifeline.

2.1. Solid vs. Clad: Choosing the Right Ground Rod

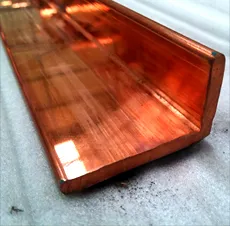

Pure copper round bar offers maximum conductivity and longevity but comes at a premium price. For cost-sensitive yet demanding projects, engineers often turn to copper bonded steel or copper clad steel ground rods. These combine the tensile strength of steel with the corrosion resistance of a thick copper layer—typically 0.25mm or more—making them ideal for rocky or corrosive soils.

- Copper bonded earthing rod: Electrolytically bonded for uniform coverage and long life.

- Copper clad earth rod: Molecularly bonded copper sheath over steel core; excellent for high-drive installations.

The earthing rod price varies significantly: solid rod copper may cost 3–4× more than copper bonded alternatives, but total lifecycle cost often favors pure copper in critical infrastructure like hospitals or power substations.

2.2. Integration with Flat Conductors

Grounding systems rarely rely on rods alone. They’re connected via flat conductors like copper strip or copper earth strip (e.g., 25x3mm). These copper metal strips—available as beryllium copper strip for spring-loaded contacts or nickel plated copper strip for enhanced oxidation resistance—ensure low-resistance paths to earth.

Interestingly, while many search for ‘copper strip near me’ or ‘copper strip price’, professionals prioritize specs over proximity: thin copper strips must meet IEC 62561 standards for lightning protection, and flexible copper bus bar variants are used where thermal expansion is a concern.

3. Copper Rod in Specialized Welding and Brazing

Beyond earthing, copper rod shines in high-precision joining applications—especially where dissimilar metals or extreme thermal cycling are involved.

3.1. Copper-to-Copper Joining in HVAC and Refrigeration

Air conditioning copper pipe networks demand absolute leak integrity. That’s where copper brazing rod and copper to copper brazing rods come in. Unlike soldering, brazing uses filler metals with melting points above 450°C, creating joints stronger than the base metal itself.

Technicians working on aircon copper tube repairs often use copper welding rod specifically formulated for refrigerant lines. The best copper rod for welding in this context contains phosphorus deoxidizers that prevent porosity without flux—critical for clean, contamination-free AC copper pipe systems.

Pro tip: When resoldering copper pipe or repairing a 15mm copper tube joint, always use oxygen-free copper rod to avoid hydrogen embrittlement during heating.

3.2. Material Selection Matters

Not all welding rod copper is equal. For high-stress applications like marine pipework or aerospace hydraulic lines, beryllium copper strip or copper alloy strip fillers offer superior fatigue resistance. Meanwhile, standard copper rod welding suffices for residential copper pipe and fittings.

Confusion often arises between copper pipe sizing (e.g., 22mm copper pipe vs. 3/4 copper tubing) and compatible rod diameters. Generally, a 2–3mm copper round bar works for most HVAC brazing tasks, whether you’re joining 1/2 copper pipe or 1 1/2 copper tubing.

4. Practical Considerations: Cost, Sourcing, and Sustainability

With volatile copper ingot prices affecting everything from copper bar top costs to ac copper pipe price, buyers must balance performance and budget. A copper bonded ground rod might save upfront, but in saline environments, solid rod copper lasts decades longer.

Recycling also plays a role. Many contractors now strip copper wire for scrap using mechanical strippers—never burning copper wire for scrap, which releases toxic fumes. The best way to strip copper cable cleanly preserves the underlying copper strip wire for reuse in bus bars or grounding straps.

For those sourcing materials, terms like ‘roll of copper strip’, ‘1mm copper strip’, or ‘copper edging strip’ reflect specific form factors needed for different applications—from EMI shielding to architectural detailing like copper roof strip.

5. Conclusion

From safeguarding billion-dollar data centers with copper clad steel earth rods to enabling leak-proof air conditioner copper pipe joints with precision copper brazing rods, the copper rod proves its worth far beyond commodity status. Whether you’re comparing earthing rod price options or selecting the right copper to copper welding rod for a critical repair, understanding these niche applications ensures safety, efficiency, and longevity. In a world demanding ever-greater reliability, the copper rod remains a foundational—yet often overlooked—engineering marvel.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Copper. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.