1. Introduction

In a major update just 24 hours ago, the International Electrotechnical Commission (IEC) released revised guidelines for grounding systems in high-voltage renewable energy installations—emphasizing the critical role of high-conductivity materials like copper rod and copper bonded earthing rod. As solar farms and offshore wind turbines expand globally, reliable earthing isn’t just about safety—it’s about system longevity and performance.

While many associate copper rods with basic electrical wiring or plumbing, their advanced applications in precision engineering, renewable energy infrastructure, and specialized metal joining reveal a far more sophisticated utility. This article dives into two niche but high-impact uses: electrical earthing and copper-to-copper welding.

2. Copper Rods in Advanced Electrical Earthing Systems

2.1. Why Copper for Earthing?

Copper’s unmatched electrical conductivity (second only to silver) and corrosion resistance make it ideal for grounding. In critical infrastructure—like data centers, telecom towers, and substations—engineers specify copper earth rod or copper bonded ground rod to ensure decades of reliable performance, even in aggressive soil conditions.

Solid copper rods offer the highest conductivity but come at a premium. That’s where copper bonded steel and copper clad steel ground rod options shine: they combine the strength of a steel core with a thick, metallurgically bonded copper layer—delivering 90%+ of pure copper’s conductivity at a fraction of the copper rod price.

2.2. Material Choices: Solid vs. Bonded vs. Clad

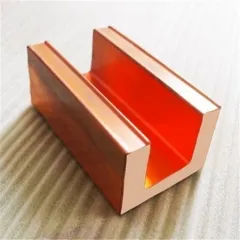

- Solid copper rod (also called copper round bar or round bar copper): Used in highly corrosive environments like coastal installations.

- Copper bonded earthing rod: Features an electrolytically deposited copper layer over high-tensile steel—ideal for deep-driven applications.

- Copper clad steel earth rod: Made by co-extruding copper over steel, offering excellent pull-out strength and conductivity.

Specifiers often compare earthing rod price versus lifecycle cost. While a copper bonded ground rod may cost 30–40% less upfront than solid copper, its performance in most soils is nearly identical—making it the go-to for large-scale projects.

2.3. Complementary Components: Copper Strips and Tapes

Earthing systems rarely rely on rods alone. Flat copper strip—especially 25x3mm copper earth strip—is commonly used to interconnect rods or bond equipment. Thin copper strips, nickel plated copper strip, or even beryllium copper strip may be selected for flexibility or anti-spark properties in explosive environments.

And yes, copper tape for snails (a garden pest deterrent) shares the same base material—but industrial copper strip near me searches usually point to suppliers of copper strip roll for electrical use, not horticulture!

3. Copper Rods in Specialized Welding and Brazing

3.1. The Challenge of Joining Copper

Welding copper is notoriously difficult due to its high thermal conductivity—it dissipates heat so fast that achieving a proper fusion zone requires specialized techniques and filler materials. This is where copper welding rod and copper brazing rod become essential.

For repairs or fabrication involving pure copper components—like heat exchangers, bus bars, or electrical connectors—engineers turn to copper to copper welding rod or copper to copper brazing rods. These fillers match the base metal’s composition, ensuring joint integrity and conductivity.

3.2. Filler Rod Selection

Not all ‘welding rod copper’ is the same. Common types include:

- Oxygen-free copper rods for high-purity applications (e.g., semiconductor manufacturing).

- Phosphorus-deoxidized copper brazing rods for joining copper pipework without flux.

- Silicon bronze or beryllium copper alloy strips for high-strength joints in marine or aerospace settings.

When working on copper pipe for AC systems—like aircon copper pipe or air conditioning copper pipe—technicians often avoid welding altogether, opting for soldering instead. But in high-temperature or high-vibration environments, copper rod welding with compatible filler may be the only viable solution.

3.3. Practical Considerations

Using copper rod for welding demands preheating (often to 400–700°F) and precise heat control. Many professionals prefer brazing with copper brazing rod because it melts at a lower temperature, reducing distortion. Regardless of method, the goal is a seamless, conductive joint that won’t fail under thermal cycling.

4. Market Trends and Pricing

With global copper prices fluctuating, buyers are increasingly comparing copper rod price versus copper bonded alternatives. A standard 16mm x 3m copper earth rod can cost 2–3x more than its copper bonded counterpart. Similarly, copper strip price varies widely by thickness—1mm copper strip or 25x3mm flat copper strip commands premium rates for high-purity grades.

Recycling also plays a role: stripping copper wire for scrap remains popular, though burning copper wire for scrap is discouraged due to toxic fumes. The best way to strip copper cable involves mechanical strippers—not fire—to preserve metal value.

5. Conclusion

From safeguarding megawatt-scale solar farms with copper bonded earthing rods to enabling flawless copper-to-copper joints in aerospace components, the humble copper rod proves its worth far beyond plumbing or basic wiring. As renewable energy and electrification accelerate, demand for high-performance copper-based grounding and joining solutions will only grow—making material selection more strategic than ever.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Copper. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.