1. Introduction

In the past 48 hours, global copper markets have seen notable volatility due to a surprise export restriction from a major South American mining nation, pushing copper rod prices upward by nearly 3%. This sudden shift has reignited interest among engineers, electricians, and recyclers in understanding the nuances between different copper-based conductors—especially copper rod, copper bonded earthing rod, and various copper strip formats.

Whether you’re sourcing a copper earth rod for grounding systems, selecting a copper brazing rod for metal joining, or stripping copper wire for scrap recycling, knowing the right type—and its cost-performance trade-offs—is critical. This deep dive breaks down the key categories, compares their properties, and helps you choose wisely based on application, budget, and durability needs.

2. Copper Rod Variants: Solid, Bonded, and Clad

2.1 Solid Copper Rod vs. Copper Bonded Steel

A pure copper rod—often called rod copper or copper round bar—is made from electrolytic-tough-pitch (ETP) copper, offering excellent conductivity and corrosion resistance. These are ideal for high-performance electrical bus bars, grounding electrodes in corrosive soils, and precision welding applications like copper to copper welding rod tasks.

However, solid copper comes at a premium. Enter copper bonded earthing rod and copper bonded ground rod options. These consist of a steel core molecularly bonded with a thick layer of copper (typically 0.25mm or more). They offer 90% of copper’s conductivity at roughly half the copper rod price, making them popular for utility-scale earthing installations.

- Advantages of solid copper rod: superior longevity, no risk of galvanic corrosion, full recyclability

- Advantages of copper bonded steel: cost-effective, high tensile strength, suitable for rocky terrain

2.2 Copper Clad Alternatives

Closely related are copper clad steel ground rods and copper clad earth rods. Unlike bonded versions, these use an electroplating or cladding process that bonds a thinner copper layer to steel. While cheaper, they’re less durable in highly acidic or saline environments. Still, for short-term or budget-sensitive projects, copper clad steel earth rod solutions remain viable.

3. Welding and Brazing: Specialized Copper Rods

Not all copper rods are for grounding. Copper brazing rod and copper welding rod types serve entirely different purposes. Copper to copper brazing rods often contain phosphorus or silver alloys to lower melting points and improve flow during capillary joining—essential in HVAC and plumbing.

For copper rod welding in electrical or industrial contexts, oxygen-free copper rods are preferred to prevent porosity. Meanwhile, welding rod copper designed for dissimilar metals may include tin or zinc additives. Always match the rod composition to your base metal; using a generic copper rod for welding can lead to weak joints or oxidation issues.

4. Copper Strip: From Earthing to Recycling

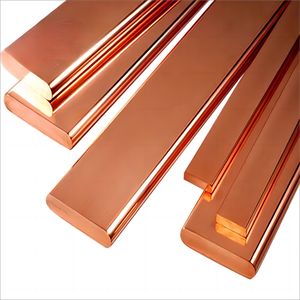

4.1 Types and Applications of Copper Strip

Beyond rods, copper strip—also called copperstrip, flat copper strip, or copper metal strips—plays a vital role in grounding, electronics, and even agriculture (yes, copper tape for snails is a real thing!). Common specs include 1mm copper strip, 25x3mm earth strips, and flexible copper bus bar rolls used in switchgear.

Specialty variants like beryllium copper strip or copper beryllium strip offer high strength and fatigue resistance, ideal for springs and connectors. Nickel plated copper strip enhances solderability and corrosion protection in harsh environments.

4.2 Stripping and Recycling Considerations

With copper strip price rising, many are turning to stripping wire for scrap. The best way to strip copper wire depends on gauge: manual strippers work for thin cables, while industrial machines handle thick bundles. Burning copper wire for scrap is illegal in many regions and damages purity—avoid it.

For those asking ‘is stripping copper wire worth it?’—yes, if done cleanly. Stripping copper wire for scrap yields higher returns than selling insulated cable. Fast ways include rotary strippers or automated systems, especially when processing roll of copper strip remnants or stripping cable for copper recovery.

5. Pricing and Sourcing Insights

Current copper rod price trends reflect not just raw material costs but also fabrication complexity. A copper earth strip 25x3mm price might range $8–$12 per meter, while copper ingot price hovers near $9,000/ton. For DIYers searching ‘copper strip near me,’ local metal suppliers often stock standard sizes like 1oz copper or 15mm copper pipe offcuts that can be repurposed.

Similarly, aircon copper pipe price varies by diameter—15mm copper tube and 22mm copper pipe are common in AC systems. Note that copper pipe for AC must be dehydrated and sealed to prevent moisture contamination, unlike general copper tubing.

6. Conclusion

From solid copper round bar to cost-efficient copper bonded ground rods and versatile copper strip rolls, the copper conductor landscape is rich with options tailored to specific engineering needs. With recent market shifts driving up copper rod price and earthing rod price alike, understanding material differences isn’t just technical—it’s financial. Whether you’re installing an earthing system, brazing copper pipework, or recycling stripped wire, choosing the right copper product ensures performance, safety, and value.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Copper. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.