1. Introduction

In the past 48 hours, global copper prices surged by over 2% following supply chain disruptions in Chile—the world’s top copper producer—due to unexpected mine maintenance halts. This volatility directly impacts copper rod price and copper strip price, making it crucial for engineers, electricians, and recyclers to understand material differences and cost drivers.

Whether you’re installing an earthing system, welding copper components, or sourcing materials for HVAC pipework, not all copper products are created equal. From solid copper round bar to copper bonded steel ground rods, each variant serves a distinct purpose with unique trade-offs in conductivity, durability, and cost.

2. Copper Rod Variants: Purpose-Built for Performance

2.1 Solid Copper Rod vs. Copper-Bonded and Clad Alternatives

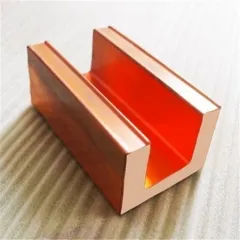

A pure copper rod—often called rod copper or copper round bar—is prized for its high electrical and thermal conductivity. It’s commonly used in bus bars, electrical connectors, and as copper rod for welding in specialized applications.

However, for grounding systems, many professionals opt for copper bonded earthing rod or copper clad steel earth rod. These combine a steel core (for tensile strength) with a thick outer layer of copper (for corrosion resistance and conductivity). The copper bonded ground rod is especially popular where deep driving into rocky soil is required.

- Copper bonded steel offers 95%+ of pure copper’s conductivity at roughly half the cost.

- Copper clad steel ground rod typically has a thinner copper layer than bonded versions, making it less durable in highly corrosive soils.

2.2 Welding and Brazing: Choosing the Right Rod

When joining copper components, the choice between copper welding rod and copper brazing rod matters. Copper to copper welding rod is rare because pure copper melts at 1,085°C and requires precise control; instead, most use copper brazing rods with silver or phosphorus alloys.

Copper to copper brazing rods (like AWS BCuP series) flow easily into joints without melting the base metal, making them ideal for plumbing and refrigeration work. Meanwhile, welding rod copper is mostly used in industrial settings with inert gas shielding.

3. Copper Strips: From Earthing to Electronics

3.1 Flat Conductors for Diverse Applications

Flat copper strip—also marketed as copperstrip, copper metal strips, or thin copper strips—comes in rolls or cut lengths. Common sizes include 25x3mm for earthing and 1mm copper strip for electronics.

Specialized variants like beryllium copper strip or nickel plated copper strip offer enhanced spring properties or oxidation resistance, respectively. Flexible copper bus bar designs often use annealed flat copper strip to handle thermal expansion in switchgear.

3.2 Pricing and Sourcing Considerations

Copper strip price fluctuates with LME rates, but standard flat copper strip near me may cost $8–$15 per kg depending on thickness and alloy. For grounding, copper earth strip 25x3mm price typically ranges from $20–$35 per meter in commercial quantities.

Recyclers often ask: ‘Is stripping copper wire worth it?’ Absolutely—if done right. Burning copper wire for scrap is illegal in many regions and damages purity. Instead, use mechanical strippers for the best way to strip copper cable cleanly.

- Best way to strip copper wire: rotary wire strippers for bulk jobs.

- Fast way to strip copper wire: automated cable peelers for industrial recycling.

- Avoid burning—it reduces resale value and releases toxic fumes.

4. Copper in HVAC and Plumbing Systems

Air conditioning copper pipe—also called aircon copper tube or AC copper pipe—is essential for refrigerant lines. Standard sizes include 1/2″, 3/4″, 15mm copper pipe, and 22mm copper tube. Proper copper pipe soldering ensures leak-free joints in both residential and commercial systems.

While PEX plumbing pipes are gaining ground in water supply, copper tubing remains dominant in high-temperature and high-reliability applications. Cleaning copper pipe before soldering is non-negotiable for strong, lasting connections.

5. Market Insights and Practical Tips

With copper ingot price hovering near $9,000/ton, alternatives like copper bonded materials help manage budgets without sacrificing performance. For grounding, compare earthing rod price across copper clad earth rod vs. solid copper options—long-term corrosion resistance often justifies the upfront cost.

For DIYers and pros alike: always verify conductivity specs. A copper clad steel ground rod might suffice for temporary sites, but permanent installations demand copper bonded or solid copper earth rods.

6. Conclusion

From copper rod welding to copper strip for earthing, understanding material composition, application requirements, and current market dynamics ensures smarter decisions. Whether you’re sourcing copper bars for sale, calculating loads on a copper bus bar, or stripping wire for recycling, matching the right copper product to the job saves time, money, and future headaches.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Copper. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.