1. Introduction

Just 24 hours ago, the London Metal Exchange reported a sharp 3.2% surge in copper prices, driven by renewed infrastructure investments in North America and Europe. This spike has reignited interest in copper-based components like copper rod, copper strip, and specialized variants such as copper bonded earthing rods. Whether you’re an electrician sourcing a ground rod copper for a substation or a recycler looking for the best way to strip copper wire, understanding the nuances between these materials is more valuable than ever.

2. Copper Rod Variants: From Earthing to Welding

Not all copper rods are created equal. The term ‘copper rod’ broadly covers several specialized forms, each engineered for distinct purposes. Let’s break them down.

2.1 Solid Copper Rod vs. Copper Bonded and Clad Alternatives

Pure copper rod—often called rod copper or round bar copper—is prized for its high conductivity and corrosion resistance. However, it’s expensive. Enter copper bonded earthing rod and copper clad steel ground rod: cost-effective hybrids where a steel core is coated with a layer of copper. Copper bonded steel uses electroplating or molecular bonding to fuse copper to steel, offering 90% of pure copper’s conductivity at half the price. Similarly, copper clad earth rod and copper clad steel earth rod serve identical roles in grounding systems but differ slightly in manufacturing processes.

- Copper bonded earthing rod: ideal for high-corrosion environments like coastal areas.

- Copper clad ground rod: often used in residential grounding due to lower cost and adequate performance.

When comparing earthing rod price points, pure copper rods can cost 2–3 times more than copper bonded alternatives, making the latter popular for large-scale projects.

2.2 Welding and Brazing Rods: Precision Tools for Joining

For metalworkers, copper brazing rod and copper welding rod serve critical—but different—functions. Copper to copper brazing rods use filler metals that melt below 450°C, creating strong joints without melting the base metal. In contrast, copper rod for welding—such as copper to copper welding rod or welding rod copper—is used in arc or TIG processes where the rod itself becomes part of the weld pool.

Key considerations include thermal expansion compatibility and joint strength. While copper rod welding delivers excellent electrical continuity, it requires skilled handling to avoid porosity and cracking.

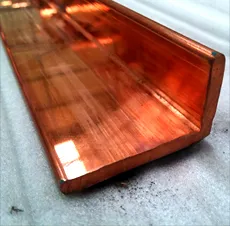

3. Copper Strip: The Flat Powerhouse

Beyond rods, flat copper forms like copper strip, copperstrip, and copper metal strips are indispensable in electrical panels, transformers, and even roofing.

3.1 Types and Industrial Uses

Flat copper strip comes in various alloys and thicknesses—from ultra-thin 1mm copper strip to robust copper earth strip 25x3mm used in substation grounding. Beryllium copper strip and copper beryllium strip offer enhanced strength for springs and connectors, while nickel plated copper strip resists oxidation in high-humidity environments.

Specialty variants include copper roof strip for architectural detailing and copper tape for snails (a niche horticultural use). For electrical safety, copper strip for earthing ensures low-resistance grounding paths in industrial facilities.

3.2 Pricing and Sourcing

Copper strip price fluctuates with LME rates, but standard flat copper strip typically ranges from $8–$15 per kg depending on purity and width. Searching for ‘copper strip near me’ often leads to local metal suppliers offering roll of copper strip or copper strip roll in bulk.

4. Stripping Copper Wire: Efficiency Meets Ethics

With copper scrap prices climbing, many turn to stripping copper wire for profit. But methods matter.

The best way to strip copper wire avoids burning—a dangerous practice that releases toxic fumes and degrades copper quality. Instead, mechanical strippers or automated machines offer a fast way to strip copper wire safely. For recyclers, stripping wire for recycling using professional tools preserves insulation integrity and fetches higher resale value.

- Never burn copper wire for scrap—it’s illegal in many regions and harms both health and metal value.

- Use precision tools for stripping copper cable, especially when dealing with thick or armored types.

Whether you’re stripping copper wire for scrap or preparing copper strip wire for reuse, ethical and efficient practices maximize returns while complying with environmental regulations.

5. Conclusion

From solid copper round bar to copper clad steel earth rod and flexible copper bus bar, the copper product ecosystem is vast and purpose-built. Understanding differences in composition, application, and cost—especially amid today’s volatile copper markets—empowers smarter purchasing, safer installation, and better recycling outcomes. As infrastructure demands grow, so does the need for informed decisions around every copper rod, strip, and tube.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Copper. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.