1. Introduction

In the past 48 hours, global copper prices have seen a slight uptick due to increased demand in renewable energy infrastructure and electric vehicle manufacturing—sectors heavily reliant on high-conductivity materials like copper rod and copper strip. This renewed interest highlights the ongoing relevance of copper in modern engineering and construction.

Whether you’re an electrician installing an earthing system, a welder joining copper components, or a recycler stripping copper wire for scrap, understanding the full range of copper products—from copper rod to copper strip and copper pipe—is essential. This guide breaks it all down in plain terms.

2. What Is a Copper Rod?

A copper rod is a solid, cylindrical bar made of pure or alloyed copper. Known for its excellent electrical and thermal conductivity, corrosion resistance, and malleability, it’s used across industries—from electrical grounding to manufacturing.

Common forms include rod copper for general use, copper round bar (also called round bar copper), and specialized variants like copper brazing rod or copper welding rod.

3. Types and Applications of Copper Rods

3.1 Earthing and Grounding Rods

For electrical safety, copper earth rod (also called earthing rod copper or ground rod copper) is critical. These rods safely channel fault currents into the earth.

Options include:

- Solid copper earth rod

- Copper bonded earthing rod (steel core with copper coating)

- Copper clad ground rod (similar to bonded but with metallurgical bonding)

- Copper clad steel earth rod and copper clad steel ground rod—cost-effective alternatives with good conductivity and strength

When comparing earthing rod price, copper bonded options often offer the best balance of performance and affordability.

3.2 Welding and Brazing Rods

For joining copper components, professionals use:

- Copper brazing rod

- Copper to copper brazing rods

- Copper welding rod or copper rod for welding

- Copper to copper welding rod (ideal for HVAC and plumbing repairs)

These rods ensure strong, conductive joints without compromising the base metal’s integrity. Copper rod welding is common in refrigeration and air conditioning systems.

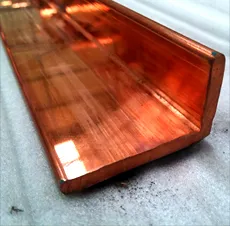

4. Copper Strips: Thin, Flat, and Versatile

Beyond rods, flat copper strip products serve many roles—from earthing to electronics. Common types include:

- Flat copper strip and thin copper strips (e.g., 1mm copper strip)

- Beryllium copper strip and copper beryllium strip (for springs and connectors)

- Nickel plated copper strip (for enhanced corrosion resistance)

- Copper strip for earthing (e.g., copper earth strip 25x3mm price varies by region)

Rolls are popular: copper strip roll or roll of copper strip makes handling easier. You’ll also find copper edging strip for architectural uses and copper roof strip for weatherproofing.

Recyclers often search for ‘copper strip near me’ or ‘best way to strip copper wire’—but avoid burning copper wire for scrap, as it’s illegal in many areas and harmful to health.

For scrap recovery, the best way to strip copper cable includes mechanical strippers or automated tools. Stripping wire for recycling or stripping copper wire for scrap can be profitable if done safely.

5. Copper Pipes and Tubing: HVAC and Plumbing Essentials

Copper pipework remains a standard in plumbing and HVAC. Air conditioning copper pipe (also called aircon copper pipe or ac copper pipe) is used in refrigerant lines due to its durability and thermal properties.

Common sizes include:

- 15mm copper pipe (or 15mm copper tube)

- 22mm copper pipe (often labeled 22mm pipe copper)

- 3/4 copper pipe and 1/2 copper tubing for residential systems

Proper copper pipe soldering ensures leak-free joints. Resoldering copper pipe without full disassembly is possible with the right flux and technique.

While PEX plumbing pipes are gaining popularity, copper pipe and fittings still dominate in high-reliability applications. Always clean copper pipe before soldering for best results.

6. Copper Bars and Ingots: Industrial Backbone

Copper bar products—like copper flat bar, flexible copper bus bar, and copper bus bar—are vital in power distribution. Cu bars conduct high currents in switchgear and transformers.

Copper ingot is the raw form used to manufacture rods, strips, and bars. Copper ingot price fluctuates with LME (London Metal Exchange) rates.

Flexible copper bar variants are used where vibration or movement occurs. For hobbyists or small-scale refiners, questions like ‘is it worth melting copper into bars?’ depend on local scrap value and equipment costs.

7. Pricing Considerations

Copper rod price, copper strip price, and ac copper pipe price all track global copper markets. As of this week, 1oz copper price hovers around $0.30–$0.35, influencing retail costs.

When sourcing materials, compare options like copper bonded vs. solid copper for grounding—copper bonded steel offers savings without major performance loss.

Always verify specs: ‘copper tubing fittings’ must match pipe sizing, and ‘copper lines’ for AC units require precise diameter (e.g., 1/2 copper pipe vs. 1 1/2 copper tubing).

8. Conclusion

From copper rod for welding to copper clad earth rod for grounding, and from stripping copper wire to installing aircon copper tube, copper’s versatility keeps it indispensable. Whether you’re buying copper bars for sale, sourcing copper strip roll, or comparing earthing rod price, knowing your options ensures better performance, safety, and value. Stay updated on copper trends—they impact everything from your workshop to the global green energy shift.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Copper. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.