1. Introduction

In the past 48 hours, global copper prices have surged due to supply chain constraints in Chile and rising demand from renewable energy projects, directly impacting the copper rod price worldwide. This volatility underscores copper’s critical role across industries—from electrical grounding to HVAC systems.

Copper rod isn’t just a metal bar—it’s a versatile backbone of modern infrastructure. Whether you’re installing an earthing system, welding copper components, or sourcing materials for electrical busbars, understanding the different types and applications of copper rod is essential.

2. What Is a Copper Rod?

A copper rod is a solid cylindrical bar made primarily of high-conductivity copper. It comes in various purities, alloys, and dimensions, tailored for specific uses like electrical conduction, mechanical strength, or thermal transfer.

Common forms include rod copper for general fabrication, copper round bar for machining, and specialized variants like beryllium copper strip for springs and connectors. These products are often sold as copper bars for sale in hardware stores or industrial suppliers.

3. Key Types and Applications

3.1 Earthing and Grounding Rods

For electrical safety, copper earth rod and earthing rod copper are vital. These include solid copper rods, copper bonded earthing rod, and copper clad steel earth rod—each offering corrosion resistance and conductivity.

Copper bonded ground rod and copper clad ground rod combine steel’s tensile strength with copper’s conductivity. They’re widely used in substations and telecom towers. When comparing options, many ask about earthing rod price versus long-term durability—copper bonded typically offers the best balance.

3.2 Welding and Brazing Rods

Copper welding rod and copper brazing rod serve distinct purposes. Copper to copper brazing rods use silver or phosphorus-based alloys to join copper without melting the base metal, ideal for plumbing and HVAC work.

Meanwhile, copper rod for welding—often labeled welding rod copper or copper to copper welding rod—is used in specialized applications like repairing electrical components or joining dissimilar metals.

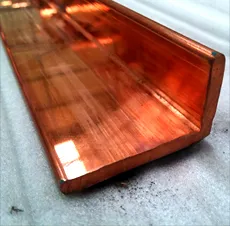

3.3 Strips, Tapes, and Flat Bars

Beyond rods, flat copper forms like copper strip, flat copper strip, and copper strip roll are indispensable. Used in busbars, transformers, and even roofing (copper roof strip), these come in thicknesses like 1mm copper strip or standard sizes such as copper earth strip 25x3mm.

Specialty variants include beryllium copper strip, nickel plated copper strip, and flexible copper bus bar for high-flexibility electrical connections. Search terms like ‘copper strip near me’ or ‘copper strip price’ reflect growing DIY and small-business interest.

3.4 Copper Tubing and Pipework

While not rods per se, copper pipework shares material origins. Air conditioning copper pipe (or aircon copper tube) is essential in HVAC systems. Sizes like 15mm copper pipe, 22mm copper tube, and 3/4 copper tubing dominate residential and commercial installations.

Proper bending copper pipe and copper pipe soldering ensure leak-free joints. Prices for ac copper pipe price fluctuate with LME copper rates, making timing crucial for contractors.

4. Recycling and Wire Stripping

With copper prices high, stripping copper wire for scrap has become increasingly profitable. The best way to strip copper wire avoids burning—a harmful practice that releases toxins and degrades metal quality.

Safe methods include manual strippers, automatic machines, or chemical processes. Tips like ‘fast way to strip copper wire’ or ‘best way to strip copper cable’ trend among recyclers. Remember: stripping wire for recycling preserves value and supports sustainability.

Never burn copper wire for scrap—it’s illegal in many areas and reduces resale worth. Instead, focus on clean stripping techniques for bare #6 copper wire or motor windings.

5. Pricing and Sourcing

Copper rod price varies by form, purity, and market conditions. Solid copper round bar costs more than copper bonded steel but offers superior conductivity. Similarly, copper ingot price influences downstream products like cu bars or copper flat bar.

When sourcing, compare options like copper clad steel ground rod versus solid copper earth rod based on environment, budget, and lifespan. For bulk buyers, checking ‘copper bars for sale’ from certified mills ensures quality and compliance.

6. Conclusion

From earthing rod copper to copper strip roll, the versatility of copper rod shapes modern engineering. Whether you’re a welder using copper rod welding, an electrician installing a copper bus bar, or a recycler stripping copper wire for scrap, understanding these materials maximizes efficiency and value.

As global demand grows—especially in green tech—the role of copper in everything from flexible copper bar to aircon copper pipe will only expand. Stay informed, choose wisely, and always prioritize safe, sustainable practices.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Copper. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.