Copper plate tends to fly under the radar — it’s not a glamorous material. But don’t let its low profile fool you. Behind the scenes, it plays a quiet yet essential role in keeping vital parts of our modern world running. What makes it so useful? Think high electrical conductivity, impressive malleability, strong corrosion resistance, and even natural antibacterial qualities. Copper plates have a wide range of uses. For engineers, architects, and procurement experts, understanding where and why copper plates excel can help achieve better, more durable, and more efficient project outcomes. Let’s explore five key industries where this crucial material forms the cornerstone of innovation, safety, and efficiency.

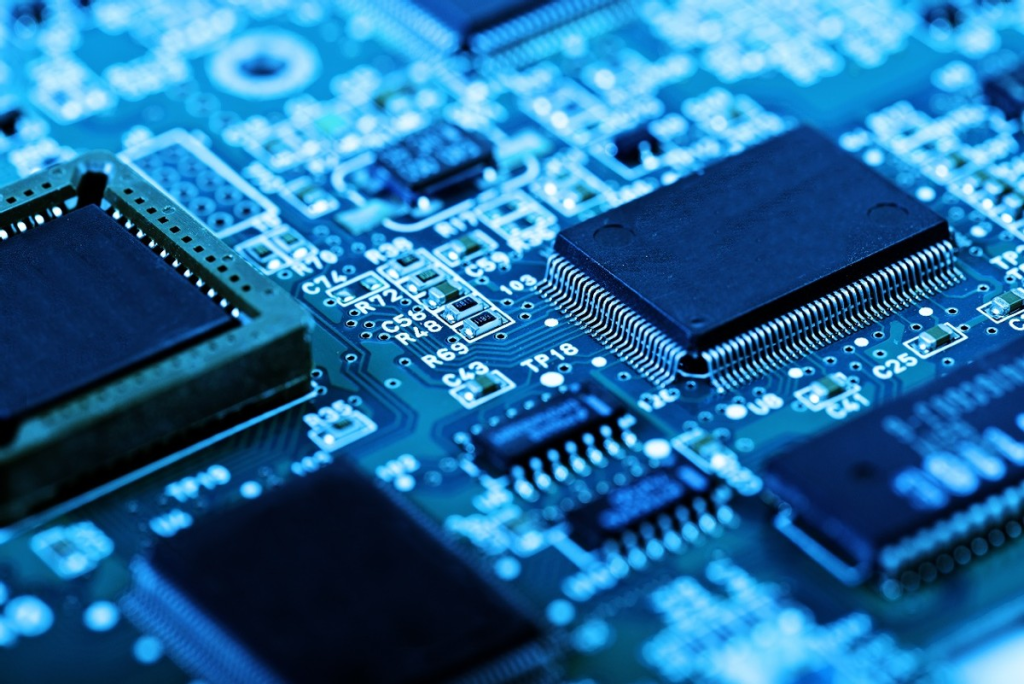

1. Electrical and Electronics

This is perhaps copper’s most famous role, and for good reason. The demand for high-purity copper plates here is immense. Copper offers the best balance of electrical conductivity, durability, and cost-effectiveness among common metals. It is the gold standard for moving electrons efficiently.

Inside large-scale power infrastructure, you find thick copper plates in power transformers and high-amperage busbars. These components form the silent, robust arteries of electrical substations and industrial facilities, conducting massive currents with minimal energy loss. This efficiency translates directly into cost savings and system reliability for power distribution networks.

In consumer and professional electronics, copper’s role becomes more refined but equally vital. Look at any printed circuit board, and you’ll find it starts with a thin sheet of copper foil bonded to the base material. That foil goes through a chemical etching process, which removes selective portions to form the delicate, micron-scale circuitry that carries electrical currents throughout the device. The purity and consistency of this copper aren’t just details—they’re what determine the final performance, processing speed, and thermal behaviour of the device, whether it’s a smartphone in your hand or a critical diagnostic machine in a hospital.

Furthermore, copper plates serve as advanced heat sinks and spreaders. In high-performance computing and communication systems, managing heat is a fundamental engineering challenge. A common and effective solution is the use of machined copper plates. These plates are placed in direct contact with heat-generating components like CPUs, GPUs, or power transistors. Leveraging copper’s superior thermal conductivity, they quickly draw heat away from these critical areas. This fanless passive cooling solution prevents devices from throttling performance due to overheating and ensures the long-term reliability of precision electronic components. In such applications, copper plate has evolved beyond being a conventional raw material—it has become an indispensable key component for enabling high device performance, miniaturisation, and stable connectivity.

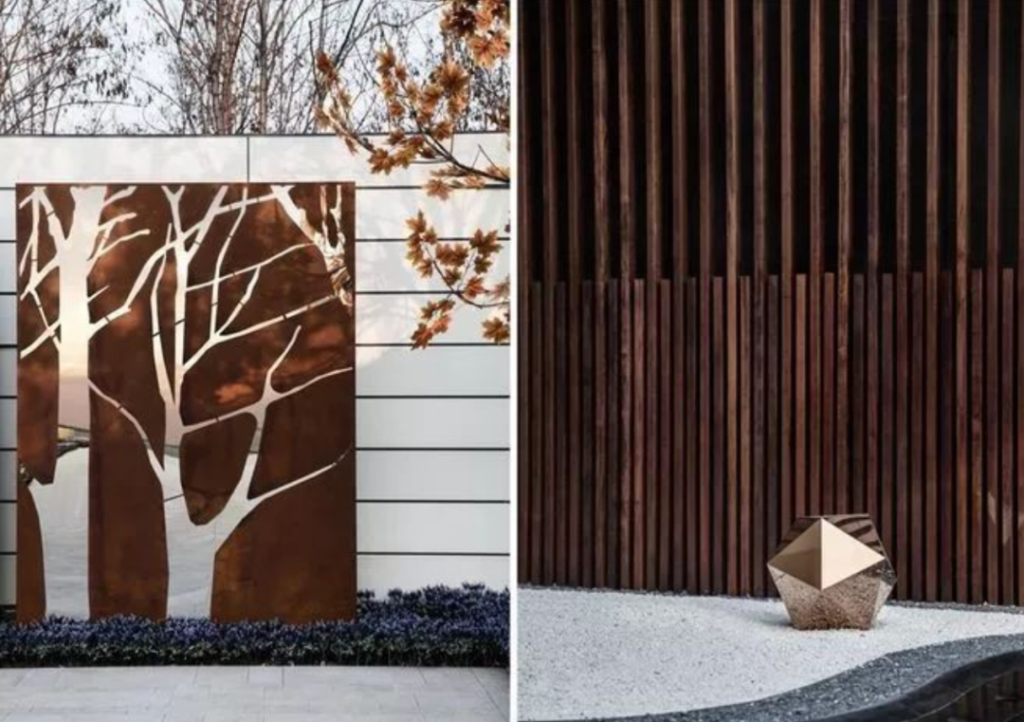

2. Architecture and Construction

Copper plate offers architects and builders a rare combination of lasting durability, visual appeal, and practical function. Its most recognisable use is in roofing, wall cladding, and building facades. Over time, exposure to the elements causes copper to develop a distinctive green patina—a natural, protective layer that actually enhances its performance and character. This patina layer is incredibly durable, allowing a copper roof to last for well over a century with virtually no maintenance. This makes it a premier choice for iconic public buildings, churches, and high-end projects where lifecycle cost and enduring beauty are paramount.

Beyond grand roofs, copper plate performs critical, unseen functions. It is the preferred material for flashing and weatherproofing details. Its malleability allows roofers to form it seamlessly around chimneys, vents, and roof valleys, creating a watertight barrier that protects the building envelope. This workability is a key advantage in complex architectural designs.

Copper also plays a non-negotiable role in safety and grounding systems. Beyond its role in safety, copper also finds purposeful use in sustainable design. It may be applied in rainwater harvesting systems or used as interior decoration. This is not just for aesthetics, but also because of its natural antibacterial properties, making it the optimal choice for handles, handrails, and high-touch surfaces. Copper is not just installed, but carefully utilised. It protects the building from the inside out, while creating a lasting aesthetic.

3. Heavy Industry and Manufacturing

In industrial environments, equipment is constantly subjected to harsh conditions such as high pressure, intense friction, extreme temperatures, and corrosive substances. At this time, copper plates, especially bronze, brass, and copper-nickel alloys, can come in handy. These materials are specifically designed to endure what would wear out ordinary metals, holding up through years of tough, daily operation.

In heavy machinery, mining equipment, and shipbuilding, copper alloys are specified for wear plates, bearing surfaces, and large bushings. These components are points of intense metal-on-metal contact. Copper-based alloys provide natural lubricity, reducing friction and galling. This minimises downtime for maintenance, reduces energy consumption from friction, and dramatically extends the service life of massive, expensive equipment.

The thermal management properties of the copper plate are indispensable in industrial heat exchange. In demanding settings like chemical plants and power stations, you’ll often find copper plates at the heart of critical cooling and heating units. It’s machined into the core of heat exchangers, shaped into condenser plates, and formed into radiator elements—all roles where moving heat reliably is the main job. Copper excels at moving heat quickly—whether between liquids, gases, or both. That’s why it’s often the first material engineers reach for in heat management. And because it holds up against steam, saltwater, and tough chemicals without corroding, the system doesn’t lose its edge over time. In facilities where every hour of uptime counts, this reliable combination doesn’t just keep things running—it allows for finer control, cuts down on energy waste, and builds in a layer of safety that operators can depend on.

4. Transportation

The transportation sector relies on materials that ensure reliability, safety, and efficiency under dynamic stresses. Copper plate delivers across maritime, automotive, and aerospace applications.

In shipbuilding and marine engineering, copper-nickel alloy plates (typically 90/10 or 70/30 Cu-Ni) are highly valued for hull sheathing and seawater system components. These alloys offer superb resistance to saltwater corrosion and, critically, to biofouling—the buildup of barnacles, algae, and mussels. This natural antifouling property reduces hull drag, leading to significant fuel savings over a vessel’s lifetime and eliminating the need for toxic antifouling paints.

The automotive revolution is deeply tied to copper. In electric and hybrid vehicles, copper plates are at the core of battery packs, power inverters, and motor windings, managing the high currents required for propulsion. That efficient conductivity and heat management aren’t just specs on a page—they’re what deliver real driving range and prevent safety-critical overheating. But copper’s role isn’t limited to new tech. Under the hood of conventional cars, you’ll find copper and brass plates hard at work in places like synchronizer rings, thrust washers, and various bearings, where their strength and resistance to wear keep gears shifting smoothly and components aligned.

5. Coinage, Art, and Specialised Craft

This final category highlights copper’s cultural, economic, and artistic significance. While modern coins rarely use pure copper, they almost universally rely on its alloys. Bronze (copper-tin) and cupronickel (copper-nickel) provide the perfect combination of properties for currency: a familiar weight and feel, resistance to wear from constant handling, a non-allergenic surface, and inherent antimicrobial benefits. The “copper” in our change is a testament to the metal’s historical role as a basis for value and trade.

Beyond economics, copper plate is a cherished medium for artists, metalworkers, and master craftsmen. Its softness accepts intricate etching, engraving, and repoussé work. Its warm, radiant colour and ability to take on a spectrum of finishes—from polished mirror to verdigris patina—make it ideal for monumental sculptures, decorative architectural panels, and jewellery.

Specialised crafts also utilise copper’s functional beauty. Artisans hand-hammer copper plates into premium cookware, where their unparalleled thermal responsiveness allows for precise, even cooking. Musical instrument makers use it for distinctive sound components. In these fields, copper plate transcends its industrial utility, becoming a material that connects functionality with human creativity, tradition, and aesthetic expression.

Conclusion

From channelling immense power across national grids to being carefully tooled into flowing artistic forms, copper plate proves its adaptability in ways few other materials can match. Its varied roles—across the five sectors we’ve explored—all come back to solving the same core needs: moving energy efficiently, enduring over time, and managing heat reliably.For engineers and buyers, that means choosing the right type of copper—the correct alloy, temper, and grade—isn’t just a technical step; it’s a decision that shapes how well a project will perform, how long it will last, and what it will truly cost to own.

About CopperGroup

CopperGroup is a trusted global copper plates supplier & manufacturer with over 12 years experience in providing super high-quality copper and relative materials. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, CopperGroup dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for copper plates, please feel free to contact us.