1. Introduction

In the past 48 hours, global copper prices have surged amid renewed industrial demand and supply chain adjustments, making cost-effective material selection more critical than ever for contractors and engineers. With copper rod and related products at the heart of electrical grounding, HVAC systems, and metal fabrication, understanding their types and applications is essential.

Whether you’re sourcing a copper earth rod for lightning protection, selecting a copper brazing rod for joining metals, or comparing copper pipe sizes for an air conditioning install, this guide breaks down everything you need to know about copper rod and its versatile cousins.

2. What Is a Copper Rod?

A copper rod—also referred to as rod copper—is a solid cylindrical bar made from high-conductivity copper. It’s widely used in electrical, construction, and manufacturing industries due to its excellent thermal and electrical conductivity, corrosion resistance, and ductility.

Copper rods come in various forms, including pure copper, copper alloys (like beryllium copper), and composite variants such as copper bonded or copper clad materials. These variations serve specific purposes, from high-strength welding to efficient grounding.

3. Types and Applications of Copper Rod

3.1. Copper Earth Rod and Grounding Solutions

For electrical safety and lightning protection, the copper earth rod (also called earthing rod copper or ground rod copper) is indispensable. These rods are driven into the soil to provide a low-resistance path for fault currents.

Common options include:

- Solid copper earth rod: high corrosion resistance but expensive.

- Copper bonded earthing rod: steel core with thick copper layer, offering strength and conductivity at lower cost.

- Copper clad ground rod or copper clad steel earth rod: similar to bonded rods but with a metallurgically bonded copper layer.

When comparing earthing rod price, copper bonded and copper clad variants often provide the best balance of performance and affordability. A standard copper earth strip 25x3mm price also varies based on market copper rates and supplier location.

3.2. Copper Rods for Joining and Fabrication

Welding and brazing applications rely heavily on specialized copper rods. For instance, copper to copper brazing rods and copper to copper welding rod types are formulated to fuse copper components without compromising conductivity.

Key products include:

- Copper brazing rod: used with flux for high-strength joints in HVAC and plumbing.

- Copper welding rod: ideal for copper rod welding in electrical busbars or repair work.

- Welding rod copper: often contains phosphorus or silver for better flow and joint integrity.

Always match the rod composition to your base metal—using a copper rod for welding on dissimilar metals may require filler alloys.

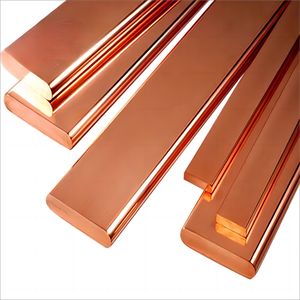

3.3. Copper Round Bar and Flat Forms

Beyond rods, copper is available as round bar copper (used in machining and electrical contacts) and flat copper strip (for busbars, shielding, or decorative edging).

Popular variants include:

- Copper strip roll or roll of copper strip: convenient for continuous applications like grounding straps.

- Thin copper strips or 1mm copper strip: used in electronics and sensors.

- Beryllium copper strip or copper beryllium strip: high-strength alloy for springs and connectors.

- Nickel plated copper strip: enhances corrosion resistance and solderability.

If you’re searching for ‘copper strip near me,’ local metal suppliers or electrical wholesalers often stock standard sizes like flat copper strip or copper edging strip.

4. Copper in Plumbing and HVAC Systems

While not rods per se, copper pipework and tubing are closely related in material and application. Air conditioning copper pipe (also called aircon copper tube or ac copper pipe) is essential for refrigerant lines due to its durability and thermal properties.

Common sizes include 15mm copper pipe, 22mm copper tube, and 3/4 copper tubing. Correct copper pipe sizing ensures system efficiency, while proper copper pipe soldering prevents leaks.

Note: PEX plumbing pipes are increasingly used as alternatives, but copper remains preferred in high-temperature or high-pressure zones.

5. Stripping and Recycling Copper

For scrap or reuse, stripping copper wire is a common task. The best way to strip copper wire depends on volume:

- Manual wire strippers for small jobs.

- Automatic strippers for long runs.

- Avoid burning copper wire for scrap—it’s illegal in many areas and damages the metal.

Stripping wire for recycling or stripping copper wire for scrap can be profitable, especially with thick insulation. The fast way to strip copper wire often involves mechanical strippers, not heat.

Similarly, stripping cable for copper or stripping copper cable should prioritize safety and metal integrity to maximize resale value.

6. Pricing and Sourcing Considerations

Copper rod price fluctuates with the LME (London Metal Exchange). As of this week, rising demand in renewable energy and EV sectors has pushed 1oz copper price upward, affecting everything from copper ingot price to copper strip price.

When sourcing:

- Compare copper bars for sale from certified suppliers.

- Consider flexible copper bus bar for dynamic electrical connections.

- Verify if you need solid copper or copper bonded steel for cost-sensitive grounding projects.

Don’t forget related items like copper bus bar, copper flat bar, or copper metal strips—all serve niche but vital roles in power distribution and electronics.

7. Conclusion

From copper rod welding to earthing and aircon copper pipe installations, copper’s versatility makes it irreplaceable across industries. Whether you need a copper bonded ground rod for lightning protection, a roll of copper strip for shielding, or the best way to strip copper wire for recycling, choosing the right form and grade ensures performance, safety, and value. Always check current copper rod price trends and source from reputable suppliers to avoid substandard materials.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Choose. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.