1. Introduction

In the past 48 hours, copper prices surged by over 3% on the London Metal Exchange following unexpected production halts at major Chilean mines—a development that directly impacts everything from copper rod price to copper strip price worldwide. This volatility underscores the importance of understanding not just what copper products you need, but which type delivers the best performance and value for your specific application.

Whether you’re installing an earthing system, brazing copper pipes for HVAC work, or stripping wire for recycling, the term ‘copper rod’ covers a surprisingly wide range of materials—each with distinct properties, costs, and use cases. In this deep dive, we’ll compare key variants like solid copper rods, copper-bonded steel, and copper-clad alternatives, while also clarifying the role of copper strips in grounding, roofing, and electrical systems.

2. Copper Rod Variants: From Pure to Composite

Not all copper rods are created equal. The choice between solid copper, copper-bonded, and copper-clad options hinges on conductivity needs, corrosion resistance, mechanical strength, and budget.

Pure copper rod—often sold as copper round bar or round bar copper—is the gold standard for high-conductivity applications like bus bars, electrical connectors, and copper to copper welding rod tasks. Its excellent thermal and electrical properties make it ideal for copper rod welding in sensitive electronics or power distribution. However, its softness and higher cost (reflected in copper rod price) can be drawbacks in structural roles.

- Solid copper rods offer superior conductivity and corrosion resistance but are expensive and less mechanically robust.

- Copper bonded earthing rod (also called earthing rod copper or ground rod copper) features a steel core electroplated with a thick layer of copper. This hybrid balances cost and performance, commonly used in grounding systems where tensile strength matters.

- Copper clad ground rod (or copper clad steel ground rod) uses a metallurgical bond to fuse copper onto steel. While slightly less conductive than bonded versions, it’s more durable during driving into rocky soil.

For those comparing earthing rod price points, copper bonded steel typically costs 30–50% less than solid copper rods while still meeting most electrical code requirements for grounding electrodes.

3. Welding and Brazing: Choosing the Right Copper Rod

When it comes to joining copper components—especially in plumbing or HVAC—the right filler material is critical. Copper brazing rod and copper to copper brazing rods are designed for high-strength joints without melting the base metal, using temperatures above 450°C.

In contrast, copper welding rod (or welding rod copper) is used in true fusion welding processes like TIG. Copper rod for welding must match the alloy of the base metal; otherwise, cracks or weak joints may form. For air conditioning copper pipe repairs, technicians often prefer brazing over welding due to easier field execution and lower equipment demands.

Note: Never use aluminum-based rods on copper systems—stick to copper-compatible fillers to avoid galvanic corrosion.

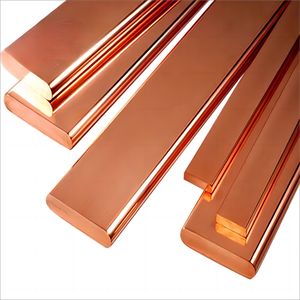

4. Copper Strips: Beyond Grounding and Scrap

While many associate copper strip with stripping copper wire for scrap, industrial applications are far broader. Flat copper strip, thin copper strips, and specialized alloys like beryllium copper strip serve roles in switchgear, RF shielding, and even snail barriers in gardens (yes, copper tape for snails is a real product!).

For electrical earthing, copper strip for earthing—often specified as copper earth strip 25x3mm—provides low-resistance paths in substations. Meanwhile, nickel plated copper strip enhances solderability and corrosion resistance in connectors.

Recyclers often ask about the best way to strip copper wire. Mechanical strippers are safest and preserve value; burning copper wire for scrap releases toxic fumes and degrades quality—avoid it. The fast way to strip copper wire involves automated cable granulators, but for DIY, manual strippers work fine for stripping wire for recycling.

Prices vary widely: a roll of copper strip might cost $20–$100+ depending on thickness (e.g., 1mm copper strip) and alloy. Search ‘copper strip near me’ for local suppliers if you need copper metal strips urgently.

5. Copper Tubing and Bus Bars: Related Essentials

Though not rods per se, copper tubing and copper bars frequently appear alongside rod discussions—especially in HVAC and power distribution. Aircon copper pipe (or ac copper pipe) comes in standard sizes like 15mm copper pipe or 22mm copper tube, selected based on copper pipe sizing charts for refrigerant flow.

Copper bus bar and flexible copper bus bar are vital in panelboards and battery systems. Made from copper flat bar or extruded profiles, they handle high currents with minimal loss. Like rods, their pricing ties closely to LME copper rates—so watch trends if you’re budgeting for copper bars for sale.

6. Conclusion

From solid copper round bar to cost-effective copper bonded ground rod, the ‘right’ copper rod depends entirely on your project’s electrical, mechanical, and economic demands. With copper prices fluctuating amid global supply concerns, understanding these distinctions helps you avoid overspending or under-specifying. Whether you’re installing a copper earth rod, resoldering copper pipe, or sourcing a copper strip roll, prioritize material compatibility, code compliance, and long-term reliability over upfront savings.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Copper. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.