1. Introduction

Just 24 hours ago, a major solar farm in Texas reported a lightning-induced system failure due to inadequate grounding—a stark reminder that even the most advanced renewable energy projects rely on fundamental components like the humble copper rod. As global investments in clean energy surge, the demand for reliable, long-lasting earthing solutions has never been higher.

While copper tubing and copper strips often steal the spotlight in HVAC or electronics, one niche yet vital application is emerging: high-performance earthing for renewable infrastructure. This article dives into how copper rod—specifically copper earth rods, copper bonded ground rods, and copper clad steel variants—are becoming indispensable in solar and wind installations worldwide.

2. Why Copper Rods Are Essential for Renewable Energy Grounding

Renewable energy sites, especially large-scale solar farms and offshore wind turbines, face extreme environmental stressors: moisture, salt spray, soil corrosion, and frequent lightning strikes. Standard galvanized steel rods degrade quickly under these conditions, risking system safety and uptime.

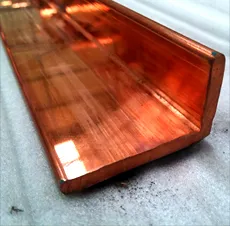

Enter the copper rod. Whether it’s a solid copper round bar or a copper bonded steel core, these rods offer superior conductivity and corrosion resistance. The term ‘earthing rod copper’ isn’t just technical jargon—it’s a specification that ensures decades of service life with minimal maintenance.

- Solid copper rods (often called copper round bar or round bar copper) provide the highest conductivity but come at a premium copper rod price.

- Copper bonded earthing rods combine a steel core for strength with a thick electrolytic copper layer for corrosion resistance—offering the best balance of performance and cost.

- Copper clad ground rods (also labeled copper clad steel ground rod or copper clad earth rod) use a metallurgical bond between copper and steel, making them ideal for rocky or high-resistivity soils.

3. Installation Best Practices for Copper Earth Rods

Installing a copper earth rod isn’t just about driving it into the ground. Proper depth, soil enhancement, and bonding techniques determine system effectiveness. Most standards recommend rods driven at least 3 meters deep to reach lower-resistivity soil layers.

When connecting multiple rods, flat copper strip or copper strip for earthing (typically 25x3mm) is used to create a low-impedance grid. The copper earth strip 25x3mm price varies by region, but its conductivity and flexibility make it a preferred choice over rigid bus bars in field applications.

Crucially, all joints must be exothermically welded or mechanically clamped—never twisted or taped. For repairs or retrofits, copper to copper brazing rods or copper welding rod may be used, though true copper rod welding requires specialized techniques to avoid embrittlement.

4. Cost vs. Performance: Navigating the Copper Rod Market

Budget-conscious engineers often ask: ‘Is a copper bonded ground rod worth the extra cost?’ The answer lies in lifecycle value. While a basic steel rod might cost less upfront, its rapid degradation leads to replacement costs and system downtime.

Compare earthing rod price points:

- Pure copper rod: Highest initial cost, longest lifespan (>50 years).

- Copper bonded steel: Mid-range price, 25–30 year service life.

- Galvanized steel: Lowest cost, often fails within 5–10 years in aggressive soils.

For large projects, bulk pricing on copper bars for sale or roll of copper strip can significantly reduce per-unit expenses. Always verify certifications—look for ASTM B843 compliance for copper bonded products.

5. Beyond Earthing: Other Niche Uses of Copper Rod in Advanced Systems

While earthing dominates industrial use, copper rods also serve in precision applications. For instance, beryllium copper strip or copper beryllium strip is used in aerospace connectors due to its spring properties and non-sparking nature.

In electronics recycling, stripping copper wire for scrap remains common—but professionals now seek thin copper strips or nickel plated copper strip for high-value recovery. However, burning copper wire for scrap is discouraged due to toxic fumes and legal restrictions.

Meanwhile, flexible copper bus bar and copper flat bar are gaining traction in EV battery packs, where thermal management and electrical efficiency are critical. These aren’t your grandfather’s copper ingot—they’re engineered alloys designed for modern demands.

6. Conclusion

From desert solar arrays to offshore wind platforms, the copper rod—whether solid, bonded, or clad—remains a silent guardian of electrical safety and system reliability. Its role may be niche, but its impact is massive. As renewable energy expands, so too will the need for intelligent material choices that balance performance, longevity, and cost. When it comes to grounding, there’s simply no substitute for quality copper.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Use. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.