1. Introduction

In the past 48 hours, global copper prices surged past $9,000 per metric ton amid supply chain concerns in Chile and rising demand from renewable energy infrastructure—a trend directly impacting the cost of copper rod and related products worldwide. This volatility makes understanding the nuances between copper rod types more critical than ever for professionals making procurement or installation decisions.

Whether you’re grounding an electrical substation, brazing HVAC components, or sourcing materials for scrap recycling, not all copper rods are created equal. From solid electrolytic-tough-pitch (ETP) copper to copper-bonded steel hybrids, each variant serves distinct purposes. In this deep-dive analysis, we’ll compare key categories—including copper earth rods, copper brazing rods, and copper round bars—and clarify where alternatives like copper strip or copper pipe might be better suited.

2. Copper Rods for Electrical Earthing: Solid vs. Bonded vs. Clad

When it comes to grounding systems, the terms ‘copper earth rod,’ ‘earthing rod copper,’ and ‘ground rod copper’ are often used interchangeably—but material composition varies significantly.

2.1 Solid Copper Earth Rods

Pure copper rods (typically ETP Cu with >99.9% purity) offer excellent conductivity and corrosion resistance. They’re ideal for high-moisture or chemically aggressive soils. However, their high copper rod price—often 3–5x that of alternatives—limits use to critical infrastructure like telecom towers or data centers.

2.2 Copper Bonded Earthing Rods

Copper bonded earthing rods consist of a mild steel core electroplated with a thick layer of copper (usually 0.25mm or more). These combine the tensile strength of steel with copper’s conductivity. They’re widely used in commercial buildings and cost less than solid copper. The term ‘copper bonded’ refers specifically to this manufacturing method, and products like copper bonded ground rod or copper bonded steel are common in North America and Europe.

2.3 Copper Clad Ground Rods

Often confused with bonded rods, copper clad steel ground rods use a metallurgical bonding process (not electroplating), resulting in a more uniform copper layer. Variants include copper clad earth rod and copper clad steel earth rod. While slightly pricier than bonded versions, they offer superior longevity in corrosive environments. For many installers, the earthing rod price difference is justified by extended service life.

3. Copper Rods for Joining Metals: Brazing vs. Welding

Not all ‘copper rods’ are for grounding. Many are consumables used in metal joining.

3.1 Copper Brazing Rods

Copper brazing rod—especially copper to copper brazing rods—are essential in HVAC and refrigeration work. These rods melt at lower temperatures (around 1,100°F) than base metals, allowing strong capillary joints without melting the parent material. They’re commonly used with aircon copper pipe systems during installation or repair.

3.2 Copper Welding Rods

True copper welding rod (or copper rod for welding) is rare because pure copper is difficult to weld due to high thermal conductivity. Instead, alloys like silicon bronze or beryllium-copper are used. Terms like copper to copper welding rod or welding rod copper usually refer to filler metals for TIG or MIG processes in specialized industrial settings—not DIY plumbing.

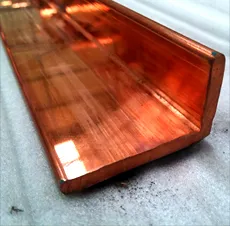

4. Copper Strip and Flat Bar Alternatives

While rod-shaped conductors dominate earthing, flat conductors like copper strip are preferred for equipotential bonding or busbar applications.

Flat copper strip, beryllium copper strip, and nickel plated copper strip serve niche roles in electronics and power distribution. Sizes like 1mm copper strip or copper earth strip 25x3mm are standard. Pricing (copper strip price) fluctuates with LME rates, and buyers often search for ‘copper strip near me’ or ‘roll of copper strip’ for local availability.

Recyclers frequently ask about the best way to strip copper wire—especially when recovering copper strip wire from motors or cables. Burning copper wire for scrap is illegal in many regions and damages quality; mechanical stripping or using a dedicated stripper is the fast way to strip copper wire safely and profitably.

5. How Copper Rod Relates to Other Copper Forms

It’s easy to confuse copper rod with similar products. Copper round bar and round bar copper are essentially the same—solid cylindrical stock used in machining or as raw material for drawing wire. Meanwhile, copper bar, copper flat bar, and flexible copper bus bar serve electrical distribution roles.

In plumbing, copper pipework—like 15mm copper pipe or 22mm copper tube—is soldered using copper pipe fittings, not welding rods. Air conditioning copper pipe (also called aircon copper tube) requires precise bending and cleaning but uses entirely different joining methods than industrial copper rod welding.

For scrap handlers, stripping copper wire for recycling remains lucrative, but knowing whether you have bare #6 copper wire or insulated cable affects value. The best way to strip copper cable depends on volume: manual tools for small jobs, automated strippers for bulk.

6. Conclusion

Choosing the right copper rod depends entirely on application. For earthing, weigh upfront cost against longevity: solid copper for mission-critical sites, copper bonded or copper clad for general use. For metal joining, brazing rods suit most copper-to-copper HVAC tasks, while true welding requires alloyed fillers. And don’t overlook flat alternatives like copper strip for bonding or busbars. With copper prices volatile and regulations tightening—especially around scrap handling—informed selection isn’t just smart engineering—it’s economic necessity.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What’s. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.