1. Introduction

In the past 48 hours, global copper markets have seen a sharp uptick in demand due to increased infrastructure spending in renewable energy projects—particularly in grounding systems that rely heavily on high-conductivity materials like copper rod. This surge has directly impacted copper rod price and availability worldwide, making it more important than ever to understand which type of copper rod suits your specific application.

Whether you’re installing an earthing system, performing copper rod welding, or stripping copper wire for scrap, not all copper rods are created equal. In this deep-dive analysis, we’ll break down the major categories—from solid copper earth rods to copper-bonded steel variants—and compare their performance, cost, and ideal use cases.

2. Solid Copper Rod vs. Copper-Bonded and Copper-Clad Alternatives

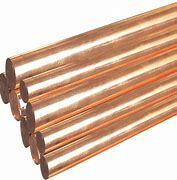

2.1. Pure Copper Rod (Rod Copper)

Solid copper rod—often called rod copper or copper round bar—is made from high-purity electrolytic-tough-pitch (ETP) copper. It offers excellent electrical conductivity (typically over 100% IACS) and corrosion resistance, making it ideal for critical applications like bus bars, grounding electrodes, and electrical connectors.

However, pure copper rods are expensive. The copper rod price for a standard 5/8-inch diameter, 8-foot rod can be 2–3 times higher than alternatives, which limits their use in large-scale civil projects where budget matters.

2.2. Copper Bonded Earthing Rod

A copper bonded earthing rod consists of a mild steel core electroplated with a thick layer of copper (usually 0.25mm or more). This hybrid design combines the tensile strength of steel with the conductivity and corrosion resistance of copper.

These rods are widely used in telecom towers, substations, and lightning protection systems. They’re significantly cheaper than solid copper, and the earthing rod price typically reflects this cost advantage without sacrificing much performance in most soil conditions.

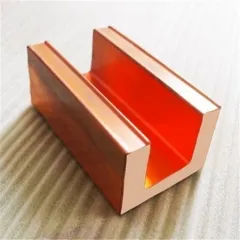

2.3. Copper Clad Ground Rod Variants

Copper clad steel ground rods (also labeled copper clad earth rod or copper clad steel earth rod) use a metallurgical bonding process to fuse copper onto a steel core. Unlike electroplating, this creates a more durable interface that resists delamination during driving or thermal cycling.

While slightly pricier than copper bonded options, copper clad rods offer better longevity in corrosive soils. Both copper bonded and copper clad types meet IEEE 80 and IEC 62305 standards for grounding—but only if the copper layer meets minimum thickness requirements.

3. Specialized Copper Rods: Welding and Brazing Applications

3.1. Copper Brazing Rod and Welding Variants

When joining copper components—like in HVAC or plumbing—you’ll encounter copper brazing rod or copper to copper brazing rods. These aren’t structural rods but filler metals designed to melt at lower temperatures than base copper, enabling strong, leak-proof joints without melting the workpiece.

Common alloys include BCuP (copper-phosphorus) for copper-to-copper joints and ERCu for TIG welding. A copper to copper welding rod ensures compatibility and avoids galvanic corrosion, which is why professionals avoid generic welding rod copper for critical systems.

3.2. Copper Rod for Welding: Key Considerations

Using the wrong copper rod welding material can lead to brittle joints or poor conductivity. Always match the filler metal to the base alloy. For example, beryllium copper strip requires specialized welding rods due to its hardening properties—never use standard copper welding rod on high-strength copper alloys.

4. Copper Strip and Related Flat Products

Beyond round rods, flat conductors like copper strip play vital roles in grounding, roofing, and electronics. Products range from thin copper strips (e.g., 1mm copper strip) to heavy-duty copper earth strip 25x3mm used in substation grids.

Nickel plated copper strip enhances solderability and reduces oxidation, while beryllium copper strip offers spring-like resilience for contacts and switches. If you’re searching for ‘copper strip near me’ or ‘roll of copper strip,’ note that flexible copper bus bar versions are gaining popularity in EV battery packs due to vibration resistance.

Recyclers often ask about the best way to strip copper wire—especially when dealing with copper strip wire or stripping cable for copper recovery. Burning copper wire for scrap is illegal in many regions and damages purity; mechanical strippers or automated machines offer a fast way to strip copper wire safely and profitably.

5. Pricing and Market Trends

Current copper rod price and copper strip price fluctuate daily with LME rates. As of this week, rising demand for copper bonded ground rod in solar farms has tightened supply chains, pushing earthing rod price up by nearly 8% in North America.

Similarly, ac copper pipe price and aircon copper tube costs are climbing due to HVAC sector growth—though that’s a separate (but related) market. For buyers, sourcing copper bars for sale or copper ingot in bulk may offset per-unit costs, especially for projects requiring both copper round bar and flat copper strip.

6. Conclusion

Choosing the right copper rod depends entirely on your application: pure rod copper for maximum conductivity, copper bonded earthing rod for cost-effective grounding, or specialized copper brazing rod for reliable joints. With copper prices volatile and regulations tightening around scrap handling (like banning burning copper wire for scrap), informed selection isn’t just smart—it’s essential. Whether you need a ground rod copper for lightning protection or a flexible copper bus bar for power distribution, matching material to function ensures safety, compliance, and value.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What’s. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.