1. Introduction

In the past 48 hours, global copper prices have surged amid supply chain constraints and rising demand from renewable energy and electric vehicle sectors, according to the London Metal Exchange (LME). This volatility directly impacts the cost and availability of copper-based products, including the widely used copper rod.

Copper rod is a fundamental industrial material valued for its exceptional electrical and thermal conductivity, corrosion resistance, and malleability. From electrical grounding systems to precision welding applications, copper rods serve as critical components across multiple sectors.

2. Types and Variants of Copper Rod

2.1. Standard Copper Rod and Round Bar

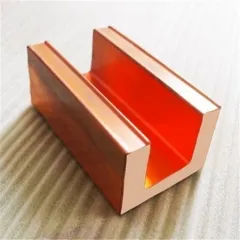

The standard copper rod, often referred to as copper round bar or round bar copper, is typically manufactured from high-purity electrolytic tough pitch (ETP) copper. These rods are used in electrical busbars, machinery parts, and as raw stock for further fabrication.

Common dimensions range from 3mm to over 100mm in diameter, with custom lengths available for industrial clients. The copper rod price varies based on purity, diameter, and market conditions, with recent LME fluctuations causing noticeable shifts in procurement costs.

2.2. Earthing and Grounding Rods

For electrical safety, copper earth rod and earthing rod copper variants are essential. These include solid copper rods, copper bonded earthing rods, and copper clad steel earth rods.

Copper bonded ground rods consist of a steel core electroplated with a thick layer of copper, offering high tensile strength with excellent conductivity. Similarly, copper clad ground rods and copper clad steel ground rods provide cost-effective alternatives to solid copper while maintaining performance in grounding systems.

The earthing rod price depends on length, coating thickness, and whether it is solid or composite. A typical copper earth strip 25x3mm price also reflects similar market dynamics, especially in infrastructure projects.

2.3. Welding and Brazing Rods

Specialized copper rods are formulated for joining applications. Copper welding rod, copper rod for welding, and copper to copper welding rod are designed for specific metallurgical compatibility.

Copper brazing rod and copper to copper brazing rods contain phosphorus or silver alloys to lower melting points and improve joint integrity. These are distinct from welding rod copper used in arc or MIG processes, which require shielding gases and precise heat control.

Proper selection ensures strong, conductive joints in HVAC, plumbing, and electrical assembly—critical where copper rod welding must maintain system reliability.

3. Related Copper Products and Accessories

3.1. Copper Strip and Flat Bar Variants

Beyond rods, flat copper products like copper strip, flat copper strip, and copper metal strips serve diverse roles. Applications range from flexible copper bus bars in switchgear to copper edging strip in architectural detailing.

Specialty variants include beryllium copper strip, nickel plated copper strip, and copper alloy strip—each engineered for enhanced strength, spring properties, or corrosion resistance. Thin copper strips and 1mm copper strip are common in electronics and battery interconnects.

Consumers often search for copper strip near me or roll of copper strip when sourcing materials for DIY or industrial use. Copper strip price fluctuates with base metal markets, similar to copper rod price trends.

Note: ‘Copper stip’ and ‘copperstrip’ are common misspellings; correct terminology is ‘copper strip’.

3.2. Copper Pipes and Tubing

While not rods, copper pipework and copper tubing are closely related. Air conditioning copper pipe (also called aircon copper pipe or ac copper pipe) is vital in refrigeration systems due to its thermal efficiency and durability.

Standard sizes include 15mm copper pipe, 22mm copper tube, and 3/4 copper tubing. Proper bending copper pipe and copper pipe soldering techniques ensure leak-free installations. Fittings like copper pipe connectors and copper tubing fittings complete these systems.

Current ac copper pipe price levels reflect broader copper market pressures, influencing HVAC project budgets globally.

4. Recycling and Wire Stripping Practices

Scrap recovery is a major segment of the copper economy. Stripping copper wire for scrap involves removing insulation to reclaim pure metal. The best way to strip copper wire includes mechanical strippers for small-scale operations and automated machines for bulk processing.

The fast way to strip copper wire avoids hazardous methods like burning copper wire for scrap, which releases toxic fumes and degrades metal quality. Instead, stripping wire for recycling using eco-friendly tools preserves value and complies with environmental regulations.

Similarly, stripping cable for copper and stripping copper cable efficiently supports sustainability goals while maximizing return on scrap.

5. Market Considerations and Sourcing

Buyers seeking copper bars for sale, copper ingot, or cu bars should verify material certifications—especially for electrical applications requiring high conductivity. Flexible copper bar and copper bus bar options cater to dynamic electrical load environments.

When comparing copper bonded vs. solid copper options, consider lifecycle costs: copper bonded steel offers initial savings but may degrade faster in highly corrosive soils.

For those asking ‘is stripping copper wire worth it?’, the answer depends on volume, labor costs, and current 1oz copper price—currently favorable due to recent market upticks.

6. Conclusion

Copper rod remains indispensable across modern industries due to its unmatched blend of physical and electrical properties. Whether used as an earthing rod copper, copper brazing rod, or raw copper round bar, its versatility ensures continued demand. As copper markets evolve, understanding product types, proper handling, and recycling best practices will help stakeholders optimize performance and cost-efficiency.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Copper. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.