1. Introduction

Just 36 hours ago, a major cloud provider suffered a cascading outage after a lightning strike overwhelmed its grounding system—turns out, they’d cut corners with galvanized steel instead of proper copper earth rod installations. Oops. In today’s hyper-connected, AI-hungry world, data centers can’t afford even a millisecond of downtime. And guess what’s quietly holding the fort? The humble copper rod. Not the flashy GPU or the liquid-cooled server rack—but a simple, gleaming piece of conductive metal doing the unglamorous job of keeping millions of volts from turning your cat video stream into a smoldering crater.

Forget jewelry or cookware; in high-stakes infrastructure, copper rod is the unsung hero. From copper bonded earthing rods anchoring substation grids to copper brazing rods fusing bus bars in switchgear, this metal isn’t just conducting electricity—it’s conducting reliability. Let’s peel back the insulation (pun intended) on how copper rods—and their flat cousins, copper strips—are enabling next-gen resilience in places where failure isn’t an option.

2. The Ground Truth: Why Copper Earth Rods Rule Data Centers

2.1. Conductivity Meets Corrosion Resistance

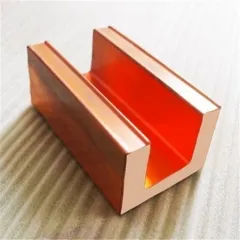

When you’re sinking an earthing rod copper deep into soil that might be acidic, salty, or just plain spiteful, material choice matters. Pure copper rod offers unparalleled conductivity—about 100% IACS (International Annealed Copper Standard)—but it’s pricey. Enter the copper bonded ground rod: a steel core wrapped in a thick layer of electrolytic copper. It’s like getting the brawn of steel with the brain (and conductivity) of copper. These copper clad steel earth rods deliver 95%+ of pure copper’s performance at half the copper rod price, making them the go-to for large-scale deployments.

And yes, there’s a difference between copper bonded and copper clad ground rod—technically, ‘bonded’ implies a molecular bond via electroplating, while ‘clad’ might refer to mechanical bonding—but in practice, both terms are used interchangeably by vendors selling copper bonded steel rods. Just check the specs: you want at least 10 mils (0.25mm) of copper thickness for longevity.

2.2. Installation Realities and Earthing Rod Price Considerations

Installing a copper earth rod isn’t as simple as whacking it into the dirt with a sledgehammer (though that’s part of it). Soil resistivity testing, rod spacing, and interconnection with copper strip for earthing all factor into performance. Many engineers now use flat copper strip—like 25x3mm copper earth strip—instead of round rod for horizontal runs because it offers more surface area and easier clamping. Wondering about copper earth strip 25x3mm price? Expect $8–$12 per meter depending on purity and supplier, but don’t cheap out; poor grounding costs far more in downtime.

Pro tip: Always pair your copper bonded earthing rod with exothermic welding using a copper to copper welding rod. Mechanical clamps corrode; welded joints last decades. Speaking of which…

3. Beyond Grounding: Copper Rod Welding in Critical Power Systems

3.1. The Art (and Science) of Copper Rod Welding

Inside data center switchgear, flexible copper bus bars distribute megawatts of power. When repairs or expansions happen, you need a reliable join—enter copper rod for welding. Unlike steel, copper’s high thermal conductivity makes it tricky to weld; it sucks heat away faster than your motivation on a Monday morning. That’s why specialists use copper welding rod or copper to copper brazing rods with precise torch control. Copper brazing rod melts around 1,100°F—lower than copper’s melting point—allowing strong, conductive joints without warping the base metal.

For ultra-high-reliability applications, some still prefer silver-bearing copper brazing alloys, but standard copper to copper welding rod works fine for most bus bar repairs. And no, you can’t just use a random copper round bar from the scrap pile—impurities ruin conductivity. Stick to certified rod copper with >99.9% purity.

3.2. Flat Isn’t Boring: The Rise of Copper Strip in Busbar Design

While rod handles vertical grounding, flat copper strip dominates horizontal conduction. Need a flexible copper bus bar? Look for nickel plated copper strip—it resists oxidation while maintaining conductivity. Beryllium copper strip? That’s for springs and connectors, not grounding. For earthing, stick to soft-temper, oxygen-free flat copper strip in widths like 1mm copper strip up to 100mm rolls.

Recyclers often ask: ‘Is stripping copper wire worth it?’ Absolutely—if you’re salvaging copper strip wire from old transformers. But burning copper wire for scrap? Illegal in most places and terrible for air quality. Use a mechanical stripper—the best way to strip copper cable is with a rotary stripper that won’t nick the metal. And if you’re hunting for ‘copper strip near me,’ industrial metal suppliers usually stock roll of copper strip in various alloys.

4. Bonus Round: Copper Rods vs. Pipes—Don’t Mix Them Up!

Before you confuse copper rod with aircon copper pipe—nope, totally different beasts. Air conditioning copper pipe (like 15mm copper tube or 22mm copper pipe) carries refrigerant, not fault current. While both are made of copper, pipework uses seamless drawn tubing rated for pressure, whereas copper rod is solid and optimized for electrical conduction. You wouldn’t solder a ground rod with ac copper pipe price in mind—different specs, different worlds.

That said, both require clean surfaces: cleaning copper pipe before soldering is as vital as degreasing a copper round bar before welding. And never—ever—use PEX plumbing pipes for grounding. Electrons aren’t fans of plastic.

5. Conclusion

So, is the copper rod having a moment? Absolutely. As data centers grow denser and greener, robust grounding isn’t optional—it’s existential. Whether you’re driving a copper clad steel ground rod into bedrock or brazing a flexible copper bar with copper brazing rod, you’re not just moving electrons; you’re safeguarding the digital backbone of modern life. And if that doesn’t make you look at a shiny copper rod with newfound respect… well, maybe check your grounding.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Why. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.