1. Introduction

Just 24 hours ago, the London Metal Exchange reported a 3.2% surge in copper prices due to renewed infrastructure investments in North America and Europe—highlighting copper’s ongoing strategic importance. Amid this volatility, one of the most versatile and widely used forms of copper remains the humble copper rod. From grounding electrical systems to enabling high-strength brazing joints, copper rods are foundational across countless industries.

But what exactly is a copper rod? And why do terms like ‘copper earth rod,’ ‘copper brazing rod,’ and ‘copper bonded ground rod’ keep popping up in technical discussions? Let’s break it all down in plain terms.

2. What Is a Copper Rod?

A copper rod—sometimes called rod copper—is a solid, cylindrical bar made primarily from high-conductivity electrolytic-tough-pitch (ETP) copper. It’s typically produced through continuous casting or extrusion and comes in various diameters, lengths, and purity levels. Its excellent electrical and thermal conductivity, corrosion resistance, and ductility make it ideal for both industrial and commercial uses.

Copper rods serve as raw material for wires, busbars, and connectors—but they’re also used directly in applications like earthing, welding, and even architectural detailing.

3. Common Types and Applications

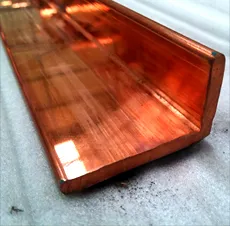

Copper rods aren’t one-size-fits-all. Their composition and coating determine their best use cases:

- Copper earth rod (also called earthing rod copper or ground rod copper): Used in electrical grounding systems to safely dissipate fault currents into the earth. These are often made from solid copper or copper-bonded steel for cost efficiency.

- Copper bonded earthing rod / copper bonded ground rod: Features a steel core with a thick outer layer of copper (typically 0.25mm or more). This combines the strength of steel with copper’s corrosion resistance. Also known as copper clad steel ground rod or copper clad earth rod.

- Copper brazing rod and copper welding rod: Used to join copper components. Copper to copper brazing rods and copper to copper welding rod types ensure strong, conductive joints without compromising integrity. Note: True ‘copper rod for welding’ is rare—most welding uses bronze or phosphor-copper alloys, but the term persists colloquially.

4. Copper Rod vs. Related Products

People often confuse copper rods with other copper forms like strips, bars, and pipes. Here’s how they differ:

Copper strip (or copperstrip) refers to flat, thin sheets—often sold as roll of copper strip or flat copper strip. Used in electronics, earthing (e.g., copper strip for earthing), and even gardening (yes, copper tape for snails is a real thing!). Variants include beryllium copper strip, nickel plated copper strip, and 1mm copper strip. Prices vary by thickness and alloy—searching ‘copper strip price’ or ‘copper strip near me’ yields local supplier options.

Copper round bar is essentially synonymous with copper rod, though ‘bar’ sometimes implies larger diameters. Flexible copper bar and copper bus bar are specialized for high-current electrical distribution.

Meanwhile, copper pipework—including aircon copper pipe, 15mm copper pipe, 22mm copper tube, and others—is used in plumbing and HVAC. While not rods, these share copper’s core benefits: durability, thermal efficiency, and ease of soldering.

5. Pricing and Market Considerations

Current copper rod price fluctuates with global markets. As of this week, prices are elevated due to supply chain adjustments and green energy projects requiring massive grounding infrastructure. Similarly, earthing rod price depends on material: solid copper rods cost more than copper bonded or copper clad steel variants—but offer longer service life in corrosive soils.

For recyclers, stripping copper wire remains popular. The best way to strip copper wire includes mechanical strippers—not burning copper wire for scrap, which is illegal in many areas and releases toxic fumes. Fast methods include automated machines for stripping wire for recycling or scrap operations.

6. Installation and Practical Tips

Installing a copper earth rod requires driving it deep into moist soil (often 8–10 feet) and connecting it via exothermic welding or listed clamps. For welding or brazing, always match the filler rod to the base metal—copper to copper welding rod ensures compatibility.

When working with copper tubing (like 3/4 copper pipe or 1/2 copper tubing), proper cleaning and soldering techniques prevent leaks. Remember: PEX plumbing pipes are replacing copper in some residential apps, but copper still dominates in AC lines and high-reliability systems.

7. Conclusion

From the copper rod anchoring your home’s electrical safety to the copper strip shielding sensitive circuits, this red metal remains irreplaceable. Whether you’re sourcing a copper bonded steel rod for a substation or comparing copper ingot price for manufacturing, understanding the nuances between rod copper, copper strip, and copper pipe helps you choose wisely—and economically.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.