1. Introduction

As of May 21, 2024, global copper prices surged past $9,000 per metric ton due to supply constraints and rising demand in renewable energy infrastructure. This spike has renewed interest in efficient copper rod usage, recycling, and proper installation—especially for earthing and welding applications. Whether you’re grounding a solar farm or salvaging scrap, knowing how to handle copper rod correctly saves time, money, and materials.

In this practical guide, we’ll cover seven real-world scenarios involving copper rod—from installing a copper earth rod to stripping copper wire fast for recycling. All steps are field-tested and optimized for safety and efficiency.

2. Installing a Copper Earth Rod for Safe Grounding

A copper earth rod (also called an earthing rod copper or ground rod copper) is essential for electrical safety. Here’s how to install one properly:

- Choose a copper bonded earthing rod or copper clad steel earth rod for durability and conductivity. Copper bonded steel offers strength with a conductive copper layer.

- Drive the rod vertically into moist soil using a hammer or driving tool—never bend it.

- Connect a copper strip for earthing (typically 25x3mm) using an exothermic weld or listed clamp.

- Test resistance with a ground resistance tester; aim for under 25 ohms.

Pro tip: Check local codes—some regions require copper bonded ground rods over solid copper for cost efficiency.

3. Welding and Brazing with Copper Rods

Copper rod for welding isn’t just one product—it varies by application. For joining copper to copper, use copper to copper brazing rods or copper welding rod designed for high-conductivity joints.

3.1. Copper to Copper Brazing

Clean both surfaces with emery cloth. Apply flux, then heat evenly with a propane or oxy-acetylene torch. Feed copper brazing rod into the joint until it flows smoothly. Let cool naturally—don’t quench.

3.2. When to Use Copper Welding Rod

For structural or high-stress joints, a copper to copper welding rod (often phosphorus-deoxidized) works better than solder. Use TIG welding with argon shielding for best results. Always preheat thick sections to avoid cracking.

Avoid using standard steel welding rods—stick to welding rod copper or copper alloy variants.

4. Choosing the Right Copper Rod Type

Not all rod copper is the same. Match the type to your job:

- Solid copper round bar: Ideal for machining or custom bus bars.

- Copper bonded steel: Best for grounding—stronger than pure copper, cheaper, and still highly conductive.

- Copper clad ground rod: Corrosion-resistant and code-compliant for most residential earthing.

Check copper rod price before buying in bulk—prices fluctuate weekly. Solid copper costs more but lasts longer in corrosive soils.

5. Stripping Copper Wire Fast and Safely

Recyclers often ask: what’s the best way to strip copper wire? Burning copper wire for scrap is illegal in many areas and toxic—never do it.

5.1. Fast Methods for Scrap Recovery

Use a manual wire stripper for small batches. For long runs, invest in an automatic stripper—some handle 100+ feet per minute.

When stripping wire for recycling, sort by type: THHN, Romex, or motor windings. Clean, bare copper fetches the highest scrap price.

5.2. Avoid Common Mistakes

- Don’t nick the copper—this reduces value.

- Never strip copper cable with knives or pliers unless absolutely necessary.

The best way to strip copper cable is with a dedicated stripping tool that adjusts to gauge size.

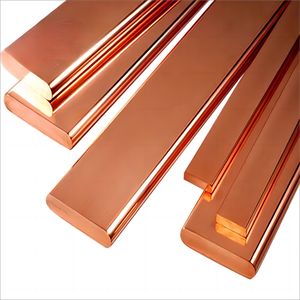

6. Working with Copper Strip and Flat Bar

Copper strip (sometimes misspelled as copper stip or copper stripes) is used in earthing, roofing, and electronics. Common forms include flat copper strip, 1mm copper strip, and copper strip roll.

6.1. Applications

- Copper roof strip: Prevents moss and algae on shingles.

- Copper strip for earthing: Connects rods to panels (e.g., copper earth strip 25x3mm).

- Beryllium copper strip or nickel plated copper strip: Used in springs and contacts.

6.2. Sourcing Tips

Search “copper strip near me” for local suppliers. Compare copper strip price per kg—bulk rolls are cheaper. Flexible copper bus bar versions are great for tight spaces.

7. Recycling and Resale Value

Is stripping copper wire worth it? Yes—if done cleanly. Bare bright copper can sell for 2–3× the price of insulated wire.

When stripping copper wire for scrap:

- Remove all plastic, rubber, or steel traces.

- Coil neatly and label by type.

- Sell to certified recyclers—avoid backyard burners.

Also consider melting copper into bars if you have large volumes, but check local regulations first.

8. Conclusion

From installing a copper bonded earthing rod to choosing the right copper brazing rod or stripping wire for top scrap value, handling copper rod effectively requires the right knowledge and tools. With copper prices rising, every gram counts—so work smart, stay safe, and always follow local codes. Whether you’re using copper round bar for fabrication or copper strip for grounding, precision pays off.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 7. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.