1. Introduction

Just 24 hours ago, the London Metal Exchange reported a 3.2% surge in copper prices due to supply chain disruptions in Chile, the world’s largest copper producer. This spike directly impacts everything from copper rod price to copper strip price, making it more crucial than ever to understand the nuances of copper products in industrial and electrical applications.

Whether you’re sourcing an earthing rod copper for a substation, selecting a copper brazing rod for plumbing, or stripping copper wire for scrap, knowing the differences between copper rod types—and their alternatives like copper strip or copper bar—can save time, money, and performance headaches.

2. Copper Rod Variants: Purpose-Driven Designs

Not all copper rods are created equal. The term ‘copper rod’ broadly covers several specialized forms, each engineered for distinct functions.

Earthing rods—often called copper earth rod, ground rod copper, or earthing rod copper—are critical for electrical safety. Pure copper rods offer excellent conductivity but are costly and soft. That’s why many opt for copper bonded earthing rod or copper clad steel ground rod. These combine a steel core for strength with a copper layer (typically 0.25mm thick) for corrosion resistance and conductivity. Copper bonded steel is especially popular in high-resistivity soils.

For joining metals, copper welding rod and copper brazing rod serve different roles. Copper to copper brazing rods (often phosphorus-copper alloys) are ideal for HVAC and plumbing without flux. In contrast, copper rod for welding—like ERCu or ERCuSi-A—is used in MIG/TIG processes for electrical or marine applications. Note: ‘copper to copper welding rod’ is a misnomer; true welding of copper usually requires alloyed filler rods, not pure copper.

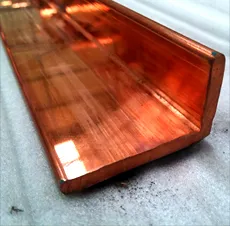

3. Copper Strip vs. Rod: When Flat Outperforms Round

While rod copper excels in structural and grounding roles, flat copper strip dominates in electrical distribution and EMI shielding. Commonly searched terms like copper strip for earthing, flat copper strip, and 1mm copper strip reflect its versatility.

Beryllium copper strip and nickel plated copper strip offer enhanced strength or corrosion resistance for aerospace and electronics. Meanwhile, copper earth strip 25x3mm is a standard size for substation grounding grids.

Recyclers often search for ‘best way to strip copper wire’ or ‘fast way to strip copper wire.’ Mechanical strippers are preferred over ‘burning copper wire for scrap,’ which releases toxic fumes and degrades copper quality. Stripping copper wire for scrap yields clean copper strip or strands that fetch higher prices than insulated cable.

4. Pricing and Material Considerations

Copper rod price fluctuates with LME rates, but composition matters too. A pure copper round bar costs significantly more than a copper bonded ground rod. Similarly, copper clad earth rod offers a mid-tier option—better conductivity than galvanized steel, lower cost than solid copper.

For HVAC technicians, aircon copper pipe price depends on diameter and wall thickness. Standard sizes like 15mm copper pipe or 22mm copper tube are widely used in air conditioning copper pipe systems. Soldering these requires proper flux and technique—resoldering copper pipe joints is common during AC retrofits.

Copper strip price varies by alloy, thickness, and form. A roll of copper strip (e.g., thin copper strips or copper strip roll) may cost $8–$15 per pound, while specialty alloys like copper beryllium strip can exceed $30/lb.

5. Practical Applications Across Industries

- Electrical grounding: copper bonded steel earth rod or solid copper earth rod for low-resistance paths.

- Plumbing and HVAC: copper pipe fittings joined with copper brazing rod; 3/4 copper tubing for refrigerant lines.

- Recycling: stripping wire for recycling using automated machines; avoiding burning copper wire for scrap.

- Manufacturing: flexible copper bus bar made from stacked copper metal strips for high-current applications.

- Construction: copper roof strip and copper edging strip for architectural detailing and lightning protection.

6. Conclusion

From earthing rod price to the best way to strip copper cable, understanding the spectrum of copper products—rod, strip, bar, and pipe—is essential for engineers, electricians, and recyclers alike. With copper prices volatile and material choices abundant (copper bonded, copper clad, pure copper), matching the right product to the job ensures performance, compliance, and cost-efficiency. Whether you need a copper round bar for machining or a copper strip near me for a grounding project, specificity pays off.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Copper. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.