1. Introduction

Just 24 hours ago, the London Metal Exchange reported a 3.2% spike in copper prices—the sharpest single-day jump since January—driven by surging demand from renewable energy infrastructure and electric vehicle manufacturing. This surge directly impacts everything from copper rod price to copper strip price, making it essential to understand the nuances between different copper products.

Whether you’re installing a grounding system, welding copper pipes, or stripping wire for scrap, not all copper rods and strips are created equal. In this deep-dive listicle, we break down seven critical categories of copper rod and strip materials, comparing their composition, use cases, advantages, and cost implications.

2. Earthing and Grounding Rods: Solid vs. Bonded vs. Clad

2.1. Solid Copper Earth Rods

Pure copper earth rods (also called earthing rod copper or ground rod copper) offer the highest conductivity and corrosion resistance. They’re ideal for high-moisture or chemically aggressive soils but come at a premium—often 2–3x the earthing rod price of alternatives.

2.2. Copper Bonded Earthing Rods

Copper bonded earthing rods feature a steel core electroplated with a thick layer of copper. This copper bonded steel construction balances cost and performance. They’re widely used in telecom and power substations where mechanical strength matters.

2.3. Copper Clad Ground Rods

Copper clad steel ground rods (or copper clad earth rods) use a metallurgical bond between copper and steel. While slightly less conductive than solid copper, they’re more durable than bonded types and resist flaking. Popular in lightning protection systems, copper clad steel earth rods offer long-term reliability at mid-range pricing.

3. Welding and Brazing Rods: Precision Joining Solutions

3.1. Copper to Copper Brazing Rods

For joining copper components without melting the base metal, copper brazing rods are essential. Copper to copper brazing rods often contain phosphorus (e.g., BCuP alloys), enabling self-fluxing action—perfect for refrigeration and plumbing.

3.2. Copper Welding Rods

True copper welding rod options (like ERCu or copper rod for welding) are used in TIG or MIG processes for high-strength joints. Copper rod welding is common in heat exchangers and electrical busbars. Note: copper to copper welding rod types require preheating due to copper’s high thermal conductivity.

4. Copper Round Bars vs. Flat Strips: Form Follows Function

4.1. Copper Round Bar Applications

Round bar copper (or copper round bar) is used in machining, electrical contacts, and as feedstock for drawing wire. Its uniform cross-section makes it ideal for turning and milling. Cu bars like these are also sold as copper bars for sale in industrial metal suppliers.

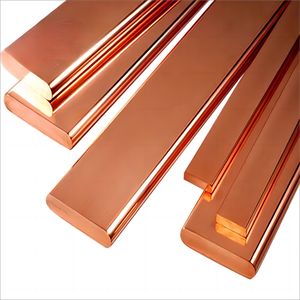

4.2. Flat Copper Strip Variants

Flat copper strips serve entirely different purposes. From copper strip for earthing (e.g., 25x3mm) to flexible copper bus bar in switchgear, these strips offer high surface-area conductivity. Specialty types include beryllium copper strip for springs and nickel plated copper strip for EMI shielding.

Thin copper strips (like 1mm copper strip) are common in electronics, while copper roof strip and copper edging strip protect building materials from weathering.

5. Copper Strip Pricing and Sourcing Trends

Copper strip price varies widely by alloy, thickness, and finish. A roll of copper strip might cost $15–$50 per kg, while beryllium copper strip can exceed $100/kg. For those searching ‘copper strip near me,’ local metal suppliers often stock standard sizes like copper earth strip 25x3mm.

Recyclers should note: stripping copper wire for scrap remains profitable, but burning copper wire for scrap is illegal in many regions and damages the metal. The best way to strip copper wire? Mechanical strippers or automated machines—never open flames.

6. Copper in HVAC: Tubing, Fittings, and Soldering

Though not rods per se, copper pipework is closely related. Air conditioning copper pipe (or aircon copper tube) dominates HVAC systems due to its thermal efficiency and durability. Common sizes include 15mm copper pipe, 22mm copper tube, and 3/4 copper tubing.

Proper copper pipe soldering requires clean surfaces and flux. Resoldering copper pipe joints without removal is possible with careful heat control. Always match pipe sizing—using 1/2 copper pipe with 1 1/2 copper tubing, for example, causes flow issues.

7. Recycling and Scrap: Maximizing Copper Value

Stripping wire for recycling is a major cottage industry. The fast way to strip copper wire involves rotary or blade strippers. For thick cables, hydraulic machines are best. Remember: stripping copper wire for scrap yields higher returns than selling insulated cable.

Avoid ‘stripping cable for copper’ by burning—it releases toxic fumes and reduces metal purity. Instead, use the best way to strip copper cable: mechanical separation. Clean, bare copper fetches top dollar, especially as 1oz copper price climbs.

8. Conclusion

From solid copper earth rods to nickel-plated copper strips, the right choice depends on conductivity needs, environmental exposure, mechanical stress, and budget. With copper prices volatile and demand rising, understanding these distinctions helps professionals optimize performance and cost. Whether you’re welding, grounding, or recycling, knowing your copper rod from your copper strip isn’t just technical—it’s economic savvy.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 7. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.