1. Introduction

Just 24 hours ago, a major cloud provider reported a localized outage traced back to a ground fault in one of its European data centers. While the incident was quickly contained, it reignited industry-wide discussions about the importance of robust earthing systems—and the often-overlooked role of the humble copper rod. In high-stakes environments like data centers, where even a microsecond of electrical instability can cause cascading failures, the choice of grounding materials isn’t just technical—it’s strategic.

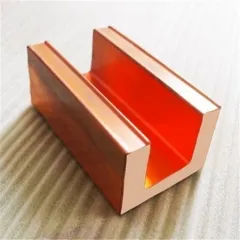

Enter the copper rod: far more than a simple metal stick, it’s a cornerstone of electrical safety and signal integrity. This article dives into how specialized forms of copper rod—like copper earth rods, copper-bonded ground rods, and copper clad steel variants—are engineered for mission-critical applications where reliability is non-negotiable.

2. The Role of Copper Rods in Data Center Earthing

Data centers demand ultra-low impedance paths to earth to protect sensitive servers, networking gear, and backup power systems from surges, lightning strikes, and static discharge. Here, the copper earth rod (also called an earthing rod copper or ground rod copper) serves as the primary interface between the facility’s electrical system and the earth itself.

Pure copper rods offer excellent conductivity and corrosion resistance, but their high copper rod price and mechanical softness can be drawbacks in rocky or high-moisture soils. That’s why many engineers now specify copper bonded earthing rods or copper clad ground rods—steel cores coated with a thick layer of electrolytic copper. These combine the tensile strength of steel with the conductivity and corrosion resistance of copper, offering a cost-effective balance.

- Copper bonded steel rods typically feature a copper layer of 0.254 mm or more

- Copper clad steel earth rods meet IEEE 837 and IEC 62561 standards for permanent earthing

- Installation depth often exceeds 3 meters to reach stable soil resistivity

3. Material Choices: Beyond the Basic Rod

Not all copper rods are created equal. For grounding, the industry distinguishes between solid copper rods, copper bonded variants, and copper clad steel earth rods. Solid rod copper is ideal for highly corrosive environments like coastal data centers but comes at a premium. Meanwhile, copper bonded ground rods deliver 90%+ of copper’s performance at a fraction of the cost—making them the go-to for large-scale deployments.

When sourcing, terms like ‘copper round bar’ or ’round bar copper’ may appear in catalogs, but these are typically used for busbars or machining, not earthing. True earthing rods are manufactured to specific diameters (usually 16mm or 5/8″) and lengths (2–3 meters) with threaded ends for coupling.

For those comparing options, checking the earthing rod price per unit—and factoring in longevity—is essential. A slightly higher upfront cost for a copper bonded earthing rod can prevent costly replacements down the line.

4. Installation and Integration with Copper Strip Systems

A single rod isn’t enough. Modern data centers use a meshed grounding grid that combines vertical copper earth rods with horizontal conductors—often flat copper strip or copper strip for earthing. These strips (available as 25x3mm, 1mm copper strip, or custom widths) interconnect rods to create an equipotential plane, minimizing voltage gradients during faults.

Flat copper strips like beryllium copper strip or nickel plated copper strip are chosen for high-flex or high-corrosion zones. Rolls of copper strip are unspooled and bonded to rods using exothermic welding or high-pressure crimps—never standard copper to copper welding rod, which lacks the required reliability.

Interestingly, while copper rod welding sounds relevant, it’s rarely used in earthing. Instead, connections rely on mechanical clamps or thermite welding to ensure low-resistance, maintenance-free joints.

5. Cost, Sourcing, and Sustainability

With copper prices fluctuating, buyers often ask: ‘Where can I find copper strip near me?’ or ‘What’s the copper strip price for a 25x3mm earth strip?’ Local electrical wholesalers or specialized grounding suppliers are best for certified materials. Beware of recycled or stripped copper wire repurposed as grounding conductors—it may not meet conductivity or durability standards.

On the scrap side, practices like burning copper wire for scrap or stripping wire for recycling are common but irrelevant to new installations. High-reliability sites use virgin or certified recycled copper only.

For budget-conscious projects, copper clad steel ground rods offer a compelling middle ground—stronger than pure copper, more conductive than galvanized steel, and competitively priced compared to solid copper rod for welding or busbar applications.

6. Conclusion

In the invisible infrastructure of data centers, the copper rod plays an outsized role. Whether it’s a solid copper earth rod, a copper bonded steel variant, or part of a larger copper strip grounding grid, this component ensures that billions of digital transactions happen safely every second. As uptime becomes more valuable than ever, investing in the right earthing materials—backed by standards, proper installation, and smart cost analysis—isn’t optional. It’s essential.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Why. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.