1. Introduction

Just 24 hours ago, a major renewable energy project in Texas announced it would use over 5,000 copper bonded earth rods to safeguard its solar farm against lightning strikes—a move highlighting how even ‘basic’ copper components are vital in cutting-edge infrastructure. While most people picture copper pipes or wires when they hear ‘copper,’ the humble copper rod has quietly become indispensable in highly specialized fields.

From aerospace manufacturing to high-efficiency grounding systems, copper rods—whether solid, clad, or alloyed—deliver unmatched conductivity, corrosion resistance, and thermal performance. Let’s dive into seven niche applications where copper rod shines.

2. High-Reliability Earthing Systems in Critical Infrastructure

Copper earth rods (also called earthing rod copper or ground rod copper) are essential for protecting data centers, telecom towers, and power substations from electrical surges. Unlike standard steel rods, copper bonded ground rods—made with a thick layer of pure copper over high-tensile steel—offer decades of corrosion resistance while maintaining low earth resistance.

Engineers often specify copper bonded steel or copper clad steel earth rods for sites with high soil acidity or moisture. The copper earth strip 25x3mm price may vary, but the long-term reliability justifies the investment. These systems rely on seamless integration with copper strip for earthing, ensuring a continuous, low-impedance path to ground.

3. Precision Brazing in Aerospace and HVAC

In aerospace assembly and air conditioning copper pipe manufacturing, copper brazing rod is the go-to filler material. Copper to copper brazing rods create strong, leak-proof joints in aircon copper tubes without melting the base metal—critical when working with thin-walled 15mm copper pipe or 22mm copper tube systems.

Technicians prefer copper brazing rod over silver-based alternatives for cost efficiency and compatibility with copper pipe soldering processes. For resoldering copper pipe joints in tight spaces, a copper rod for welding provides excellent capillary flow and joint integrity, especially in AC copper pipe installations where refrigerant leaks are unacceptable.

4. Custom Alloy Fabrication with Beryllium Copper Strip

Beyond pure copper, niche industries use specialty alloys like beryllium copper strip for springs, connectors, and non-sparking tools. These copper alloy strips—often sold as 1mm copper strip or thin copper strips—are machined from copper rod stock through precision rolling.

Beryllium copper strip offers high strength, fatigue resistance, and electrical conductivity, making it ideal for defense and oilfield applications. Flexible copper bus bars and nickel plated copper strip variants are also derived from high-purity copper round bar feedstock, showcasing how rod copper serves as the foundation for advanced conductive components.

5. Scrap Recycling and Wire Stripping Innovations

The scrap metal industry heavily relies on copper rod derivatives—especially when stripping copper wire for recycling. While burning copper wire for scrap is dangerous and illegal in many areas, modern recyclers use mechanical strippers to recover clean copper strip wire efficiently.

The best way to strip copper cable involves automated machines that separate insulation from conductors without damaging the copper. This reclaimed material often becomes feedstock for new copper ingot production or copper bars for sale. Stripping wire for scrap remains profitable, especially with rising copper rod price trends and demand for 1oz copper price stability in commodity markets.

6. Lightning Protection and Architectural Integration

Copper roof strip and copper edging strip aren’t just decorative—they’re functional elements in lightning protection systems. Paired with copper clad earth rods driven deep into the ground, these strips create a Faraday cage effect around historic buildings or sensitive labs.

Architects specify roll of copper strip or copper strip roll for both aesthetics and safety. Unlike aluminum, copper doesn’t corrode when in contact with masonry, and its natural patina adds visual appeal. For those searching ‘copper strip near me,’ suppliers often stock flat copper strip in various widths, including copper earth strip dimensions like 25x3mm.

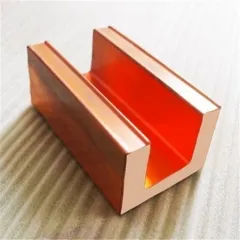

7. High-Current Busbar and Power Distribution

In industrial switchgear and EV charging stations, copper bus bar systems handle massive currents with minimal loss. These are often machined from solid copper round bar or flexible copper bar stock to accommodate thermal expansion.

Designers calculate current through a copper bus bar using cross-sectional area and ambient temperature—ensuring safety and efficiency. Copper flat bar and cu bars are preferred over aluminum due to superior conductivity and compatibility with copper wire terminations. Even in hybrid setups, using aluminum ground bar with copper wire is discouraged due to galvanic corrosion risks.

8. Conclusion

Far from being a commodity item, the copper rod is a cornerstone of modern engineering—enabling everything from lightning-safe solar farms to ultra-reliable HVAC systems. Whether it’s a copper welding rod fusing delicate aircon copper pipe or a copper bonded earthing rod shielding a 5G tower, this versatile material continues to prove its worth in the most demanding applications. As technology advances, expect even more innovative uses for rod copper across emerging industries.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 7. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.