1. Introduction

Just 24 hours ago, a major renewable energy project in Texas announced it would use over 15,000 copper earth rods to stabilize its new solar farm’s grounding system—a move driven by increasing lightning risks due to climate change. This real-world example underscores how copper rod isn’t just old-school plumbing material; it’s a critical component in tomorrow’s infrastructure.

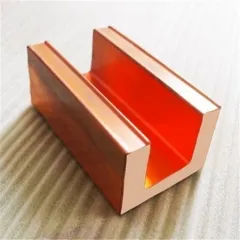

Copper rod—also referred to as rod copper, copper round bar, or round bar copper—comes in various forms and alloys, each tailored for specific high-stakes applications. From ensuring safety in high-voltage substations to enabling flawless copper-to-copper welding in aerospace assembly, its versatility is unmatched. Let’s dive into seven niche but vital uses of copper rod that fly under the radar.

2. Advanced Earthing Systems in Critical Infrastructure

2.1. Copper Earth Rods for Lightning Protection

In data centers, hospitals, and telecom towers, reliable grounding isn’t optional—it’s life-or-death. Copper earth rods (also called earthing rod copper or ground rod copper) are driven deep into the soil to dissipate dangerous surges. Pure copper rods offer superior conductivity and corrosion resistance, but cost often leads engineers to choose copper bonded earthing rods or copper clad steel ground rods.

These hybrid options—like copper bonded steel or copper clad earth rod—combine the strength of steel with the conductivity of a thick copper layer. They’re especially popular where earthing rod price is a concern but performance can’t be compromised. A standard copper earth strip 25x3mm price typically runs higher than bonded alternatives, but longevity often justifies the investment.

2.2. Copper Strip for Earthing Networks

Beyond rods, flat copper strip (sometimes called copper strip wire or copper metal strips) forms the backbone of grounding grids. Thin copper strips, 1mm copper strip, or even beryllium copper strip are used in sensitive labs and military installations. Nickel plated copper strip variants add extra corrosion resistance in coastal environments.

3. Precision Joining in Aerospace and HVAC

3.1. Copper Brazing and Welding Rods

When assembling high-purity refrigerant lines in air conditioning systems, technicians rely on copper brazing rod or copper welding rod. These aren’t your average filler metals—copper to copper brazing rods ensure leak-free joints in aircon copper pipe and ac copper pipe without introducing contaminants.

For repairs, a copper to copper welding rod enables resoldering copper pipe without disassembly. The best copper rod for welding maintains ductility and thermal conductivity, critical when working with 15mm copper pipe or 22mm copper tube in tight HVAC spaces.

3.2. Compatibility with Modern Piping

Though PEX plumbing pipes are gaining ground, copper pipe and fittings remain the gold standard for durability in commercial AC units. Proper copper pipe soldering using quality copper rod welding techniques ensures decades of service—especially important given rising ac copper pipe price volatility.

4. Recycling and Scrap Recovery Innovations

4.1. Efficient Copper Wire Stripping

The scrap industry has gotten smarter about recovering value from copper. Stripping copper wire for scrap is now done mechanically—not by burning copper wire for scrap, which is illegal and toxic. The best way to strip copper cable involves automated machines that cleanly separate insulation from conductors, preserving copper strip quality.

For hobbyists or small recyclers, the fast way to strip copper wire includes manual strippers or modified drills. Whether you’re stripping wire for recycling or sourcing copper strip near me for resale, clean, unburned copper fetches top dollar—especially as 1oz copper price climbs.

5. Electrical Busbars and Power Distribution

5.1. Flexible Copper Bus Bars in EVs

Electric vehicles and renewable inverters demand flexible copper bus bar systems that handle high current with minimal loss. Made from rolled copper strip or flexible copper bar stock, these components often use copper bars for sale in custom widths. Cu bars and copper flat bar variants are chosen for their low resistance and thermal stability.

6. Specialty Alloys in High-Tech Manufacturing

6.1. Beryllium Copper Strip for Springs and Contacts

In microelectronics and defense, beryllium copper strip (or copper beryllium strip) is prized for its strength, non-sparking nature, and conductivity. Used in connectors, switches, and even satellite components, this alloy outperforms standard copper in fatigue resistance. Rolls of copper strip in this category are tightly controlled due to material costs and regulations.

7. Architectural and Agricultural Uses

7.1. Copper Roof Strip and Pest Control

Less known but equally fascinating: copper roof strip doubles as a natural algae inhibitor on buildings. Even more niche is copper tape for snails—a gardening hack where thin copper strips create a barrier that deters mollusks through a mild electric reaction. While not high-tech, it shows copper’s adaptability beyond industry.

8. Conclusion

From stabilizing gigawatt-scale solar farms with copper clad steel earth rods to enabling flawless copper-to-copper joints in spacecraft, the humble copper rod proves its worth in the most demanding niches. Whether you’re comparing copper rod price for a grounding project or sourcing a roll of copper strip for precision manufacturing, understanding these specialized applications reveals why copper remains irreplaceable in advanced engineering.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 7. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.