1. Introduction

In the past 48 hours, global copper prices have surged due to supply chain disruptions in Chile—the world’s largest copper producer—sparking renewed interest in copper-based materials like rods, strips, and pipes among contractors, electricians, and recyclers. With copper hitting $9,200 per metric ton (as of June 2024), understanding the versatility and value of copper rod and its derivatives has never been more important.

Copper rod isn’t just a raw metal—it’s the backbone of electrical grounding, plumbing, welding, and even scrap recycling. Whether you’re installing an earthing system, repairing an AC unit, or stripping wire for resale, knowing the right type of copper product can save time, money, and effort.

2. What Is a Copper Rod?

A copper rod is a solid cylindrical bar made from high-conductivity copper, typically used in electrical, mechanical, and construction applications. Also referred to as rod copper or copper round bar, it comes in various diameters and purity grades. The most common form is electrolytic-tough-pitch (ETP) copper, known for its excellent conductivity and ductility.

3. Types of Copper Rods and Their Uses

Not all copper rods are created equal. Here’s a quick breakdown:

- Copper earth rod: Used for grounding electrical systems. Often made from solid copper or copper-bonded steel for corrosion resistance.

- Earthing rod copper / ground rod copper: Essential for lightning protection and substation grounding. Available as solid, copper bonded, or copper clad variants.

- Copper brazing rod and copper welding rod: Designed for joining copper parts. Copper to copper brazing rods and copper to copper welding rod types ensure strong, leak-free joints without base metal distortion.

- Copper rod for welding: Specifically formulated for oxy-acetylene or TIG processes when working with copper alloys.

4. Copper Bonded vs. Copper Clad Grounding Solutions

When it comes to earthing, two popular options dominate the market: copper bonded earthing rod and copper clad ground rod. Copper bonded steel features a thick electroplated copper layer over a steel core, offering high tensile strength and good conductivity. Copper clad steel ground rod (or copper clad earth rod) uses a metallurgical bond for better longevity in corrosive soils.

Both are cost-effective alternatives to solid copper rods, especially where deep driving is required. Prices vary based on length and diameter—earthing rod price typically ranges from $20 to $60 per 8-foot unit, depending on coating thickness and brand.

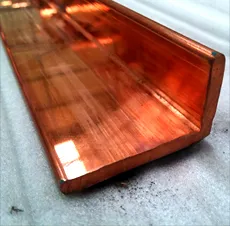

5. Copper Strips: From Earthing to Scrap Recycling

Flat copper strips—also called copper strip, flat copper strip, or copper metal strips—are widely used in busbars, transformers, and grounding systems. Common sizes include 25x3mm (used in earthing) and thin variants like 1mm copper strip.

Specialized types include beryllium copper strip (for springs and connectors), nickel plated copper strip (for EMI shielding), and flexible copper bus bar for dynamic electrical connections.

For recyclers, stripping copper wire is a daily task. The best way to strip copper wire involves using automatic strippers—not burning copper wire for scrap, which releases toxic fumes and devalues the metal. Fast methods include rotary strippers for bulk processing, while the best way to strip copper cable depends on insulation type and gauge.

6. Copper Piping: HVAC, Plumbing, and Sizing

Beyond rods and strips, copper pipe tube remains a staple in plumbing and HVAC. Air conditioning copper pipe—often called aircon copper pipe or ac copper pipe—is used in refrigerant lines due to its thermal conductivity and leak resistance.

Common sizes include 15mm copper pipe (½ inch), 22mm copper pipe (¾ inch), and 1¼ or 2½ copper tubing for larger systems. Proper copper pipe soldering ensures durable, watertight joints, while bending copper pipe requires spring benders or hydraulic tools to avoid kinks.

Note: While PEX plumbing pipes are gaining popularity, copper lines still dominate in commercial and high-efficiency residential AC installations. Current ac copper pipe price averages $8–$15 per linear foot, depending on wall thickness (Type L vs. M).

7. Pricing and Availability Trends

With rising demand in renewable energy and EV infrastructure, copper rod price and copper strip price have seen upward pressure. A standard copper round bar (1-inch diameter, 12 ft) now costs $120–$180, while a roll of copper strip may run $50–$200 based on width and alloy.

For those searching ‘copper strip near me’ or ‘copper bars for sale,’ local metal suppliers and online industrial retailers offer both solid and flexible copper bar options. Copper ingot price also influences fabricated product costs—currently around $8.50–$9.50 per pound.

8. Practical Tips for Working with Copper

Whether you’re resoldering copper pipe or installing a copper earth strip 25x3mm, here are a few pro tips:

- Always clean copper surfaces before soldering or brazing to ensure adhesion.

- Use copper pipe fittings that match your tubing type (e.g., Type L for high-pressure AC lines).

- For grounding, verify local codes—some regions require minimum copper thickness in earthing rods.

- When stripping wire for recycling, avoid acid baths or open-flame methods; they’re illegal in many areas and reduce scrap value.

9. Sustainability and Recycling

Copper is 100% recyclable without quality loss. Stripping copper wire for scrap not only pays well (bare bright copper fetches top dollar) but also reduces mining demand. Recycling centers prefer cleanly stripped copper strip wire over insulated bundles.

10. Conclusion

From copper rod welding to copper roof strip applications, copper’s unmatched conductivity, corrosion resistance, and recyclability make it indispensable across industries. As prices fluctuate and green tech booms, understanding the nuances of copper products—from copper bonded steel rods to beryllium copper strip—empowers smarter purchasing, installation, and recycling decisions.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 10. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.